Kev piav txog

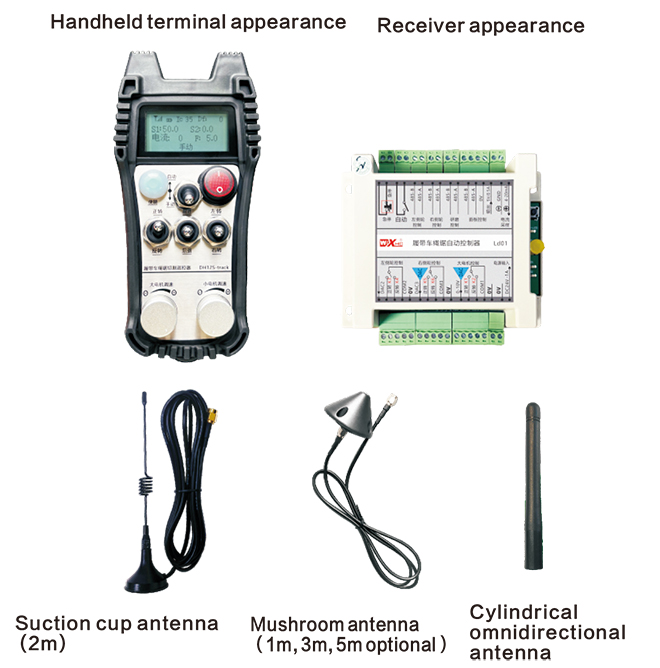

Qauv Khoom Qauv

Tus qauv: DH12s-LD

Muaj cov cuab yeej siv tau:Crawler hlau kaw tshuab

Daim Duab

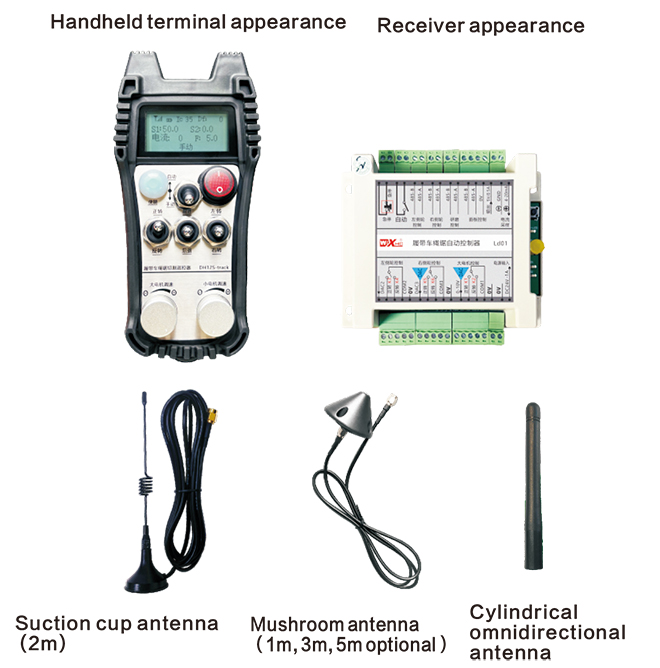

Tsab ntawv: Koj tuaj yeem xaiv ib ntawm peb tus kav hlau txais xov. Lub khob xaim tshuaj tiv thaiv tus kav hlau txais xov yog qauv los ntawm lub neej ntawd.

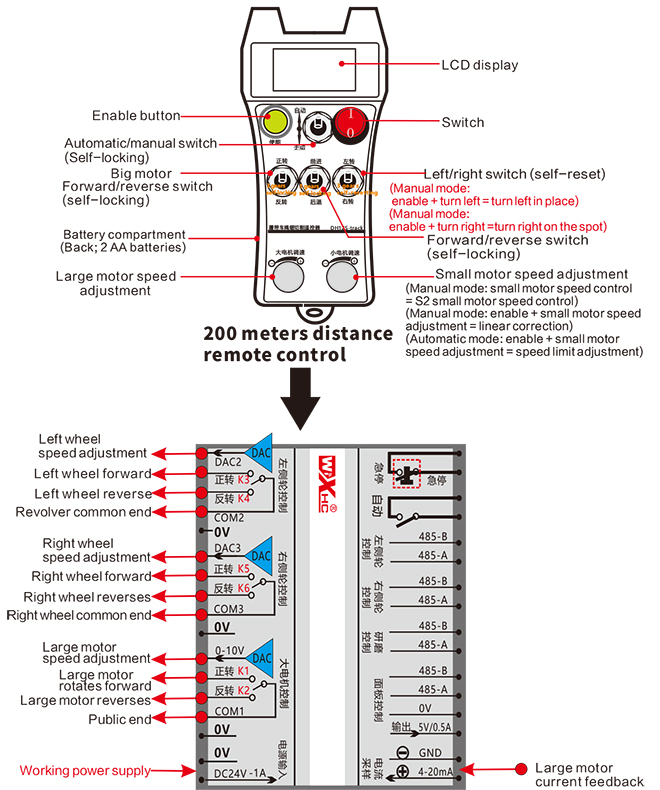

Chaw Taws Teeb Tswm Hloov

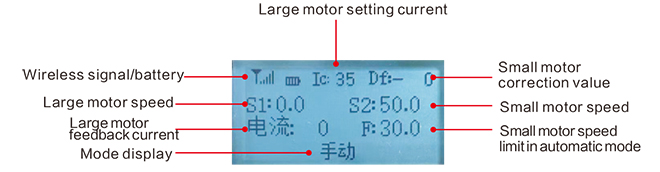

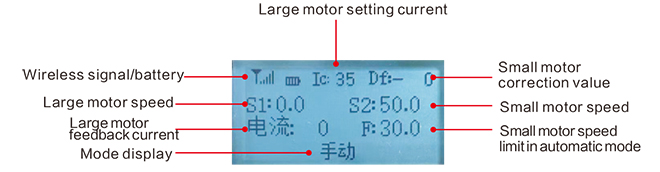

DisplayConent Soj Ntsuam

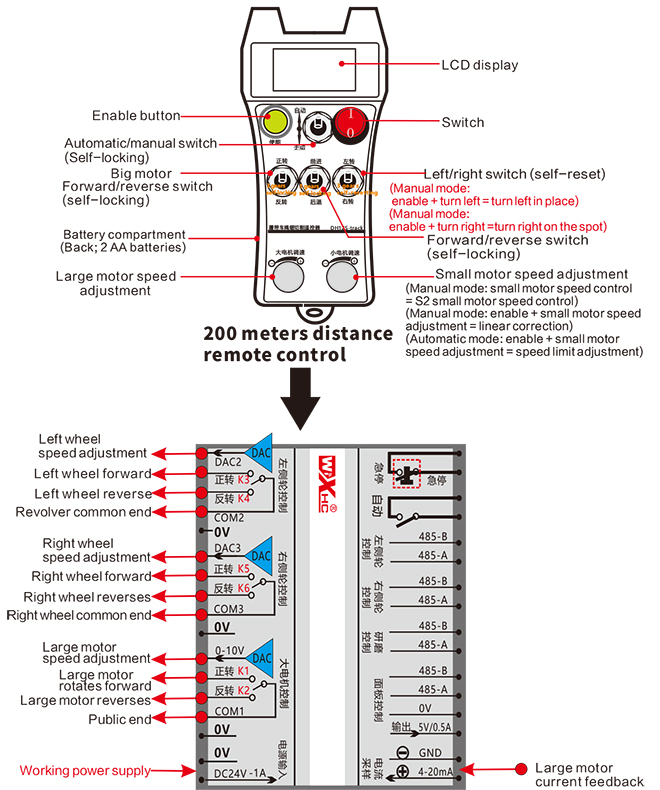

Loj Tsav Ceev Ceev:S1:0-50

Lub cev muaj zog me me: S2: 0-50

Qhov siab tshaj plaws:F:0-30(tsis muaj dab tsi)

Tsis Siv Neeg Txiav Siab Ntau Tam Sim No: Tus ic: 0-35 (tsis txhob hloov tau)

Linear kho tus nqi: Df: -99-99 (1 Chav tsev yog li 0.02V)

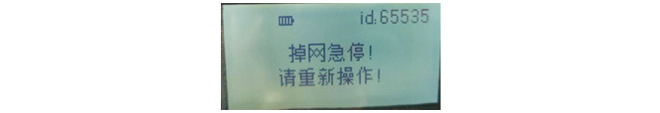

Tsawg qes: Cov chaw taws teeb tswj cov roj teeb yog tsawg heev, Thov hloov lub roj teeb.

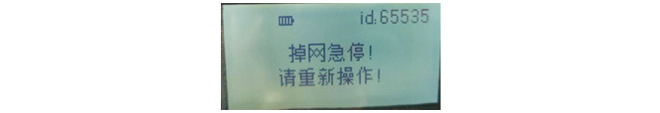

Network poob: Lub teeb liab wireless cuam tshuam. Thov kos lub zog ntawm tus txais, Lub hwj chim nws dua, thiab rov pib kho cov chaw taws teeb.

Chaw taws teeb tswj kev ua haujlwm ua haujlwm ua haujlwm

1.Tig rau ntawm cov chaw taws teeb tswj

Thaum lub powered rau, RF-LED lub teeb rau ntawm tus txais nyiaj pib rau Flash;Nruab ob lub roj teeb AA hauv throeceiver e cov chaw taws teeb tsuj, Qhib lub hwj chim hloov, Andthe cov zaub yuav qhia qhov kev nrawm nrawm, qhia tau tias muaj kev vam meej pib.

2.Loj Tsav Thiab Kev Tswj Ceev

Tig lub “Forward / Rov Qab” hloov mus rau tom ntej, Tus txais lub cev muaj zog loj yuav qhib, thiab cov zaub yuav qhia rau pem hauv ntej

Tig lub “Forward / Rov Qab” hloov mus rov qab, Lub cev muaj zog loj ntawm tus txais yuav tig rov qab, thiab cov zaub yuav qhia rov qab

Tig lub “Loj Tsav Nkaus Ceev” Lub pob qhov rooj los kho tus txais loj ceev ceev ceev hloov cov khoom siv voltage 0-10V;

3.ME MOJ THIAB CEEV COV KHIB

Txav mus “Forward / Rov Qab” hloov mus rau tom ntej, Lub log sab laug rau pem hauv ntej thiab txoj cai log rau pem hauv ntej ntawm tus txais yog muab, thiab cov zaub qhia rau pem hauv ntej

Tig lub “Forward / Rov Qab” hloov mus rov qab, sab laug lub log rov qab thiab txoj cai lub log rov qab ntawm tus txais yuav muab rau, thiab cov zaub qhia rov qab

4.Lem sab laug thiab sab xis

Tig lub “Sab laug / sab xis” Hloov mus rau sab laug, tus txais lub log sab xis yuav xa mus thiab tig mus,thiab cov zaub yuav qhia sab laug

Tig lub “lem sab laug / sab xis” hloov mus rau lem sab xis, lub log sab laug ntawm tus txais yuav xa mus rau pem hauv ntej thiab tig rau, thiab cov zaub yuav qhia sab xis lem

5.Tig rau hauv qhov chaw

Hauv phau ntawv hom:

Lem sab laug hauv qhov chaw: Nias thiab tuav tus “Ua kom txawj” lub khawm, tig lub “Sab laug / sab xis” Hloov mus rau sab laug, lub log sab laug rov qab thiab txoj cai log rau pem hauv ntej ntawm tus txais yuav muab rau,thiab pib tig mus rau hauv qhov chaw;

Lem sab xis hauv qhov chaw: Nias thiab tuav tus “Ua kom txawj” lub khawm, tig lub “Sab laug / sab xis” hloov mus rau sab xis, lub log sab laug rau pem hauv ntej thiab txoj cai log rov qab ntawm tus txais yog muab, thiab tus tau txais pib tig mus sab xis;

6.ME MOJ ME TSAV CEEV CEEV

Hauv hom hom: nias thiab tuav tus “Ua kom txawj” khawm thiab tig lub “Kev hloov kho me me ceev” Txhawm rau kho qhov siab tshaj plaws ntawm lub cev muaj zog me me thaum tsis siv neeg txiav;

7.Tsis Siv Neeg Txiav

Thawj kauj ruam yog pib lub cev muaj zog loj; kauj ruam thib ob yog hloov txoj kev hloov mus rau “Nws pib”; Qhov thib peb theem yog los pib lub cev muaj zog me me thiab lub vijtsam yuav tso saib “Txiav nws pib”,taw qhia tias nws tau nkag mus rau hom kev txiav txim siab tsis siv neeg;

8. Kev kho kab ncaj nraim

Thaum sab laug thiab sab xis taug kev lub cev ntas tau mus rau pem hauv ntej thiab rov qab, sab laug thiab sab xis nrawm yog qhov tsis sib xws, thiab txoj kab ncaj taug kev ruam. Koj tuaj yeem siv Txoj Kev Kho Mob Tawm Tsam ntawm cov chaw taws teeb tswj kom nplua-Qhib qhov ceev ntawm sab laug thiab sab xis log;

Kho kho kab ke: Los ntawm kev kho cov haujlwm, Qhov ceev ntawm lub log sab laug yog qhov zoo-tuned mus txog rau tib lub nrawm raws li lub log sab xis, yog li ua synchronize qhov ceev ntawm sab laug thiab sab xis log thiab tshem tawm cov kev sib txawv;

Kev sib txawv ntawm txoj kev ua haujlwm: Hauv phau ntawv hom, nias thiab tuav tus “Ua kom txawj” khawm thiab tig lub “Kev cai me me me”;

Tig moos ua kom nce lub log sab laug nrawm nrawm thiab tus nqi kho tus nqi ntawm cov zaub screen yuav nce ntxiv;

Tig counterclockwise kom txo qis lub log sab laug nrawm voltage thiab cov zaub kho kom tsawg dua;

Kho kho ntau yam: Kev kho tus nqi -90 rau 90; Kev kho kev kho hluav taws xob ntawm ib txoj kev kho kho yog hais txog 0.02V;

9. Parameter Menu (cov neeg siv raug txwv tsis pub hloov kho nws yam tsis tau kev tso cai)

Qee lub zog ntawm cov chaw taws teeb tswj tau tuaj yeem hloov kho los ntawm kev txwv. Hauv phau ntawv hom, Thaum lub cev muaj zog me me S2 yog 10, thawb rau pem hauv ntej / rov qab hloov peb zaug uake, thiab tom qab ntawd thawb nws cia peb zaug nyob rau hauv kab los ntaus cov ntawv qhia zaub mov parameter;

Tawm ntawm Parameter Menu: Xaiv kom txuag tau lossis tsis txuag, Tom qab ntawd nias lub pob nyem kom paub meej tias qhov kev tawm;

Qhov siab tshaj plaws: Cov kev ua haujlwm ntawm kev txiav txim siab tam sim no ntawm kev txiav lub cev muaj zog yog 80% ntawm no tam sim no;

Kev tswj kom ceev: Tsis Siv Neeg Txiav Tswj Xyuas, tsis ua li raug txib lawm 800, Kev hloov kho yog txwv tsis pub;

Deceleration Parameter: Tsis Siv Neeg Txiav Tswj Parameter. Thaum tus txiav tam sim no hloov tus nqi tshaj tus nqi no,deceleration pib.

Kev nrawm A1: Tsis Siv Neeg Txiav Tswj Parameter, Thaum qhov txiav tam sim no qis dua qhov teeb txiav tam sim no, Qhov ceev ntawm kev ua kom nrawm;

Deceleration A2: Tsis Siv Neeg Txiav Tswj Parameter, Thaum qhov txiav tam sim no siab dua li cov teeb

Txiav tam sim no, Qhov ceev ntawm deceleration;

Tsis Siv Neeg Riam Tawm: tsis yog;

Pib Lub Taub Hau Rau Tus Kheej: 0, Tsis muaj tus kheej xauv; 1, Kev txhav tus kheej. Nias lub qhov tseem ceeb + rau pem hauv ntej thiab thim rov qab los siv cov nyhuv thiab tus kheej xauv.

Qhov siab tshaj plaws taug kev: qhov siab tshaj plaws ntawm lub cev muaj zog me me.

Txiav tam sim no: teeb qhov siab tshaj plaws tam sim no ntawm lub cev muaj zog tseem ceeb rau kev txiav. Yog tias cov lus qhia tam sim no tshaj li tus nqi no, Nws yuav pib decelerate.

Adefault Kev Txwv Ceev: lub neej ntawd lub sijhawm nrawm ntawm tsis siv neeg txiav ceev thaum tig ntawm lub tshuab.

Tsis siv neeg hom: 0, Tsis siv neeg hloov yog tswj tau cia; 1, Tsis siv neeg hloov chaw tswj kav IO tso zis taw tes.

Kev Ceev Tshaj Tawm Offset: qhov siab tshaj plaws ntawm lub cev muaj zog me me thaum tsis siv neeg txiav.

Siab Tshaj Lej: Qhov ntau tshaj plaws ntawm lub cev muaj zog loj.

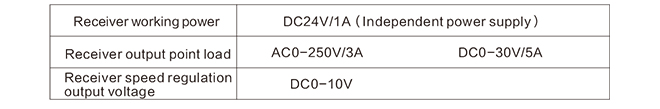

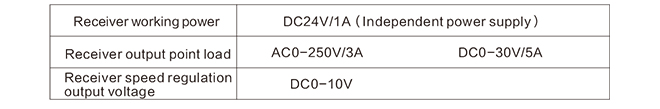

Cov Chaw Taws Teeb Hluav Taws Xob Hluav Taws Xob

Chaw taws teeb tswj qhov loj

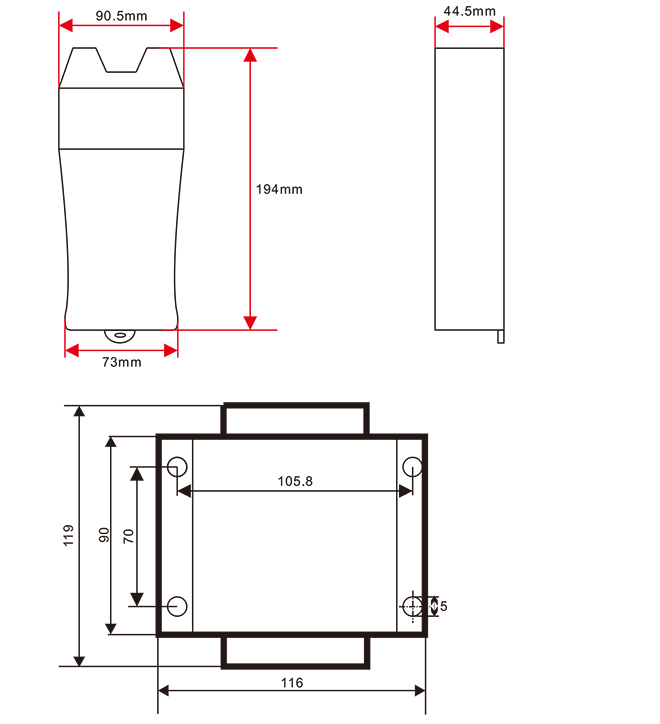

Qhov kawg txhais tau txoj cai ntawm cov khoom no tsuas yog rau peb lub tuam txhab.