Cov lus piav qhia

1.Taw qhia txog cov chaw taws teeb tswj

a. Khoom Composition

Siemens lub sijhawm tiag tiag coordinate zaub wireless hluav taws xob handwheel muaj ob ntu: hluav taws xob handwheel + receiver;

b. Cov yam ntxwv

*Support Siemens PLC: S7-200/-300/-1200;Support real-time display of Siemens system coordinate values;

*The wireless transmission distance is open 40 meters, tsis siv neeg zaus hopping technology, tuaj yeem siv 32 teeb tsa ntawm cov khoom siv tib lub sijhawm;

*Lub tshuab hluav taws xob yog siv los ntawm 2 AA roj teeb thiab tuaj yeem siv rau ntau dua li 30 Hnub;

*Lub receiver yog nruab nrog ib tug sab nraud kav hlau txais xov los txhim khu lub teeb liab thiab yog ib qho yooj yim rau nruab;

*Hluav taws xob handwheel txhawb nqa: one 100PPR encoder 、one 6-speed axis selection switch 、 one 3-speed magnification switch;

*Hluav taws xob handwheel txhawb nqa 6 Kev cai nyees khawm, corresponding to Siemens PLC address, which can be freely programmed;

*6 custom buttons can control 6 switch outputs;

*The display screen displays the PLC corresponding register coordinate value in real time, and supports 6-axis display of real-time coordinates.

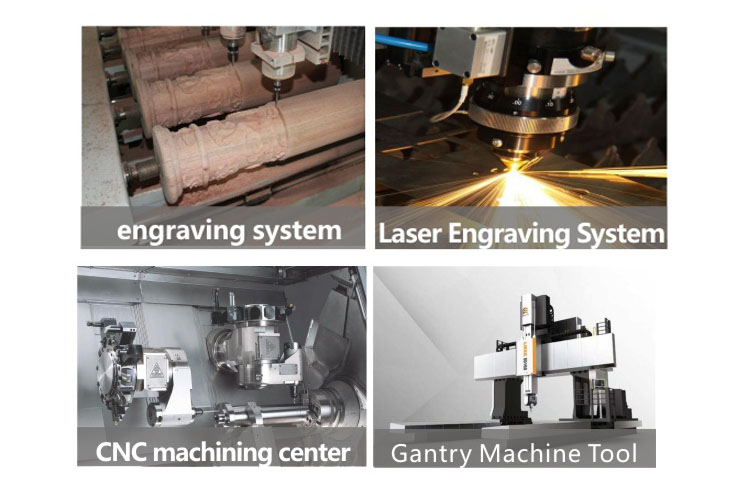

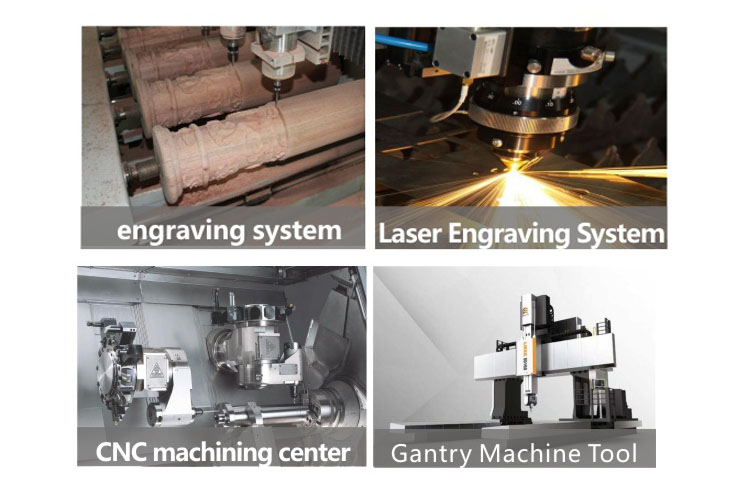

2.Application field

Programmable CNC remote control is widely used in various CNC fields such as laser engraving system, CNC Milling Tshuab, CNC Machining Center, gantry machine tool, etc.

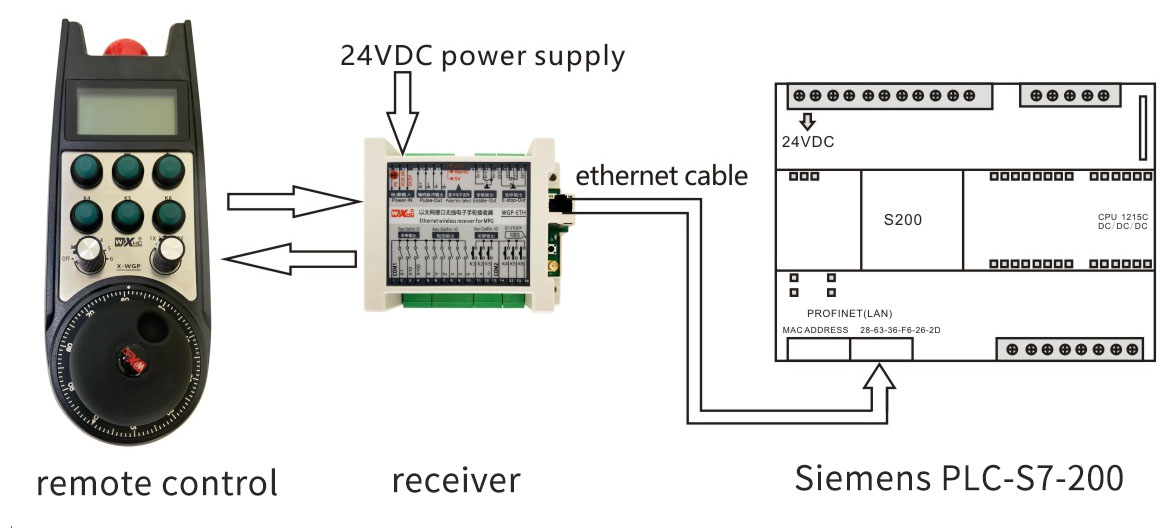

3. Introduction to the working principle

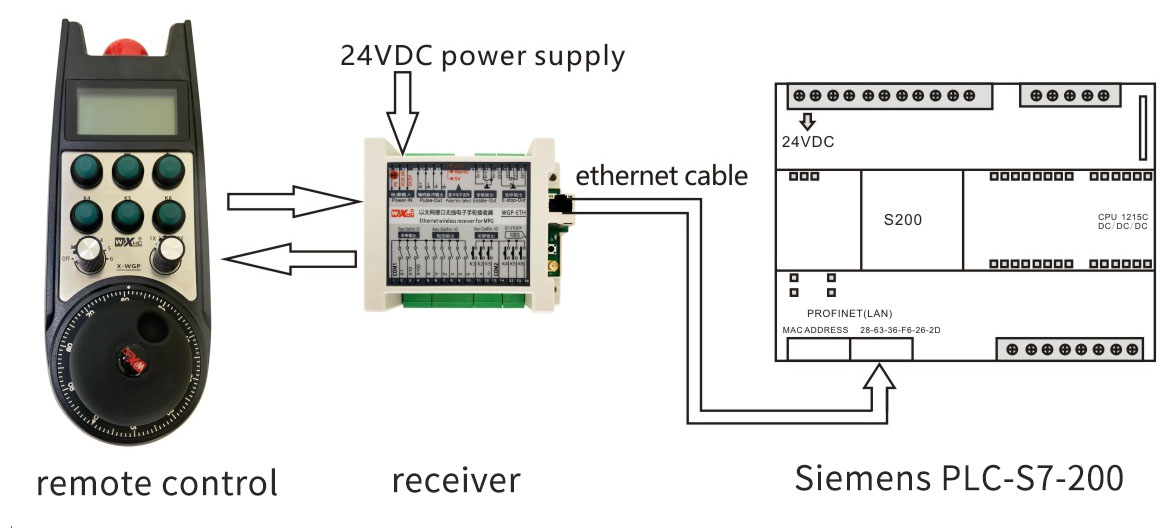

1)Electronic handwheel is connected to PLC via Ethernet receiver

a.The handwheel transmits the key data wirelessly to the receiver, and the receiver writes the keys through the network cable PLC system DB area; the receiver reads the data to be displayed from the designated DB area, and then returns the data to the handwheel display screen. The user can customize the base address of reading and writing DB area on the handwheel, so that the handwheel can read and write the data in the DB area of the PLC.

b. The receiver supports Siemens S7 protocol. Applies to PLC S7-200, PLC S7-300 and PLC S7-1200.

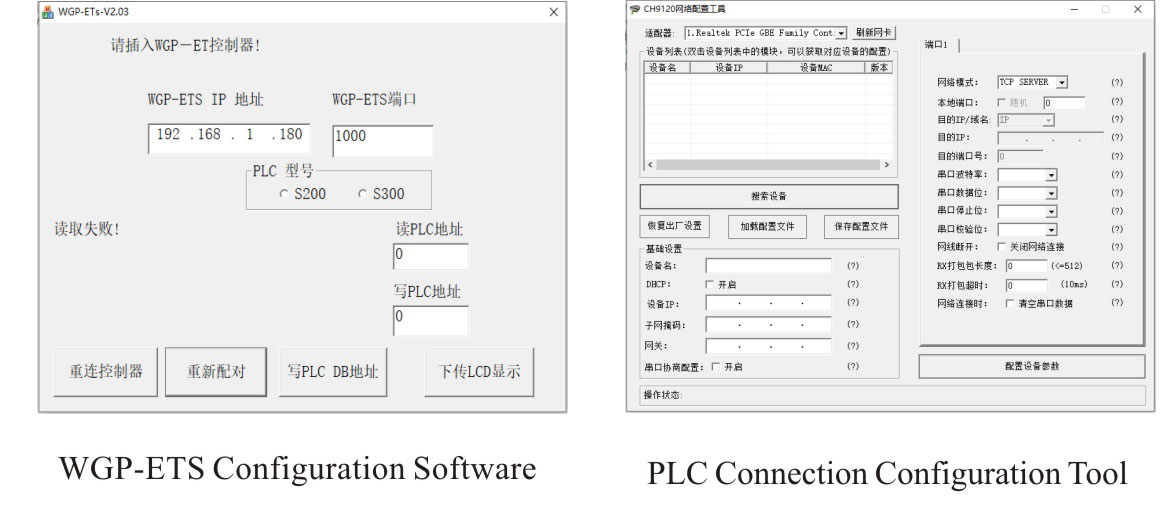

c. The user can configure the receiver to server mode and client mode through the PLC connection configuration tool.

In the server mode, the user configures the PLC read and write address through the WGP-ETS configuration software;Use the PLC connection configuration tool to configure the receiver into client mode. After configuration, the XWGP-ETS receiver can communicate with the PLC through the standard S7 protocol.

2)Specific application

Specific application of handwheel receiver and Siemens PLC S7-200:

a. The button on the handwheel corresponds to the value of the BOOL area set by the user in the PLC. If the button of the handwheel is pressed, the corresponding BOOL area is true, and when it is released, it is false, and the base address of the BOOL area can be set through the handwheel;

b. The handwheel can read the value of the DB area in the PLC. One axis has 4 bytes of display data, and 6 axes have a total of 24 bytes. The base address of the DB area can be set through the WGP-ETS configuration software.

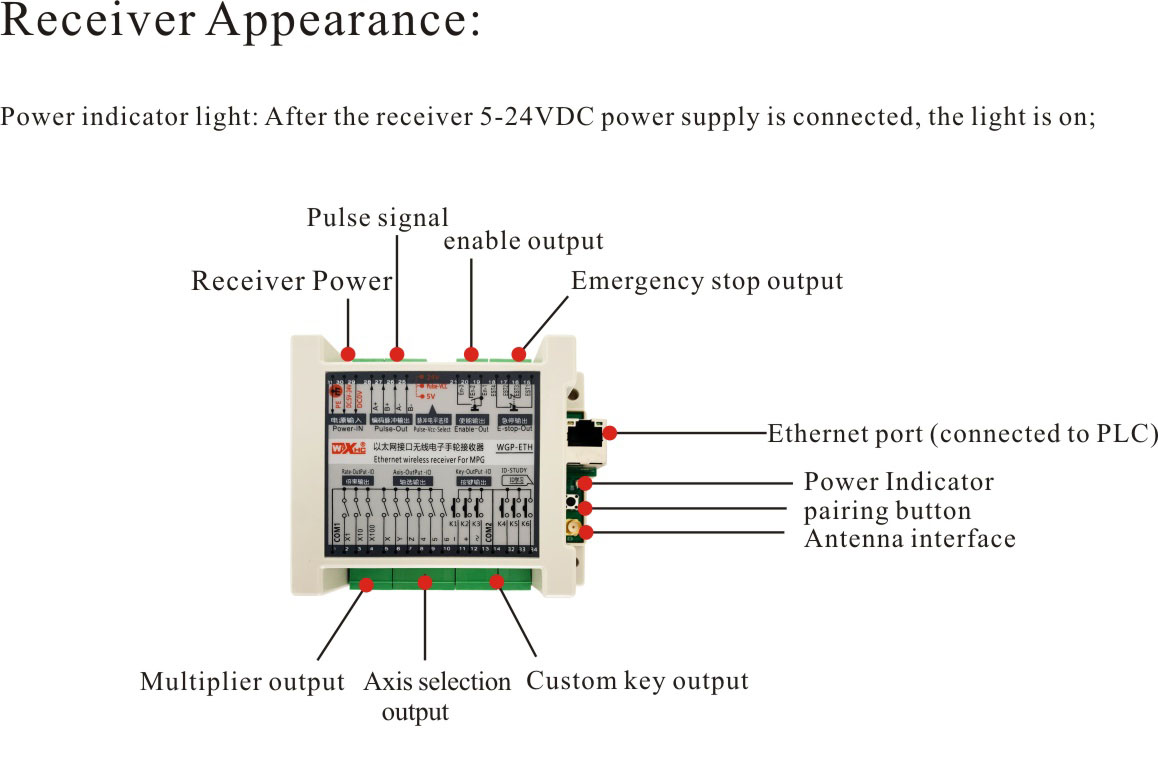

4.Appearance introduction

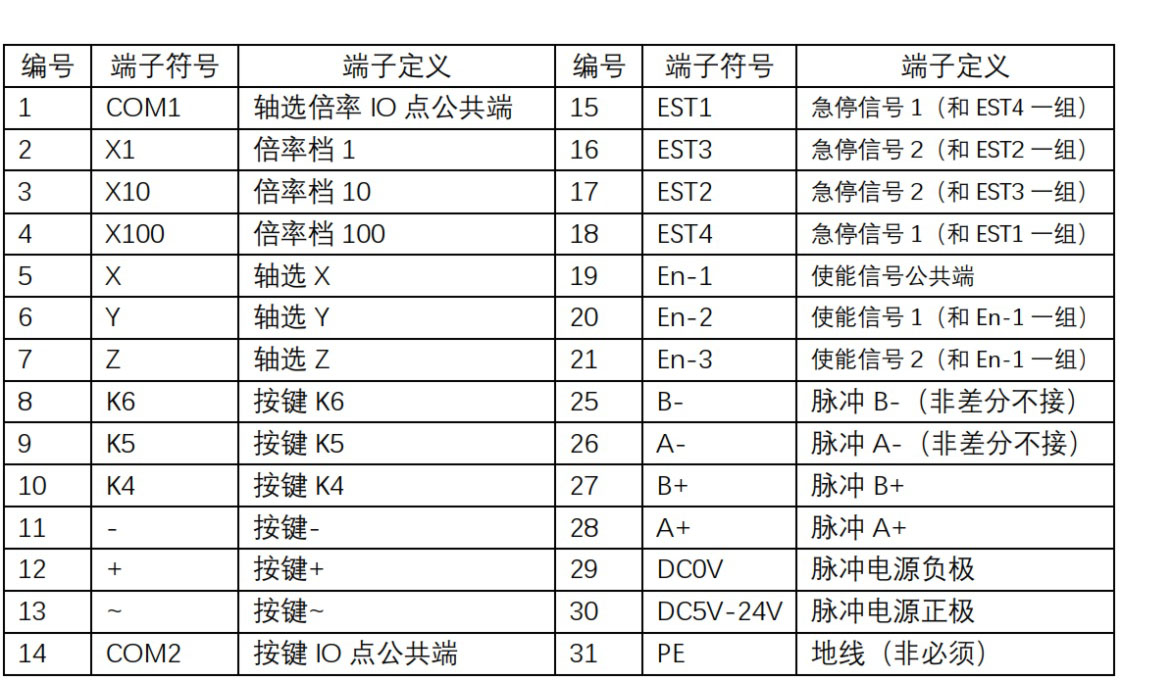

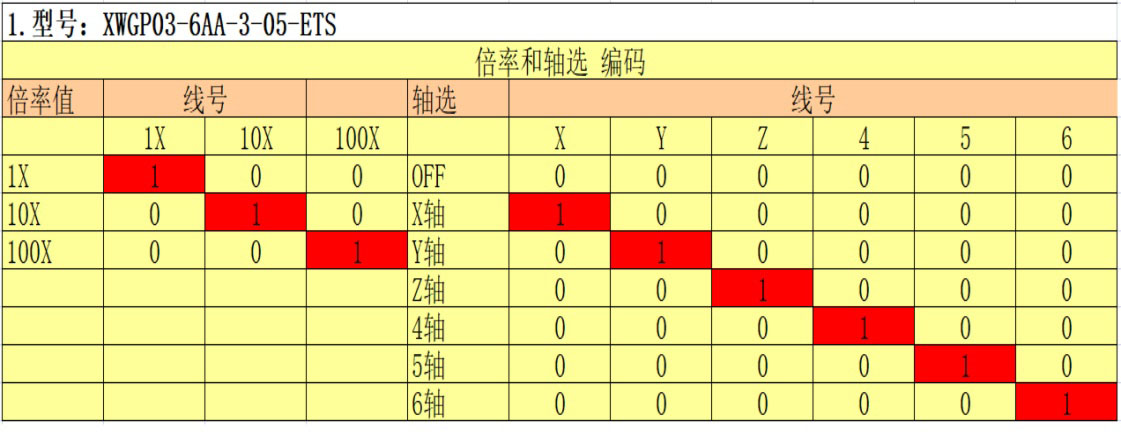

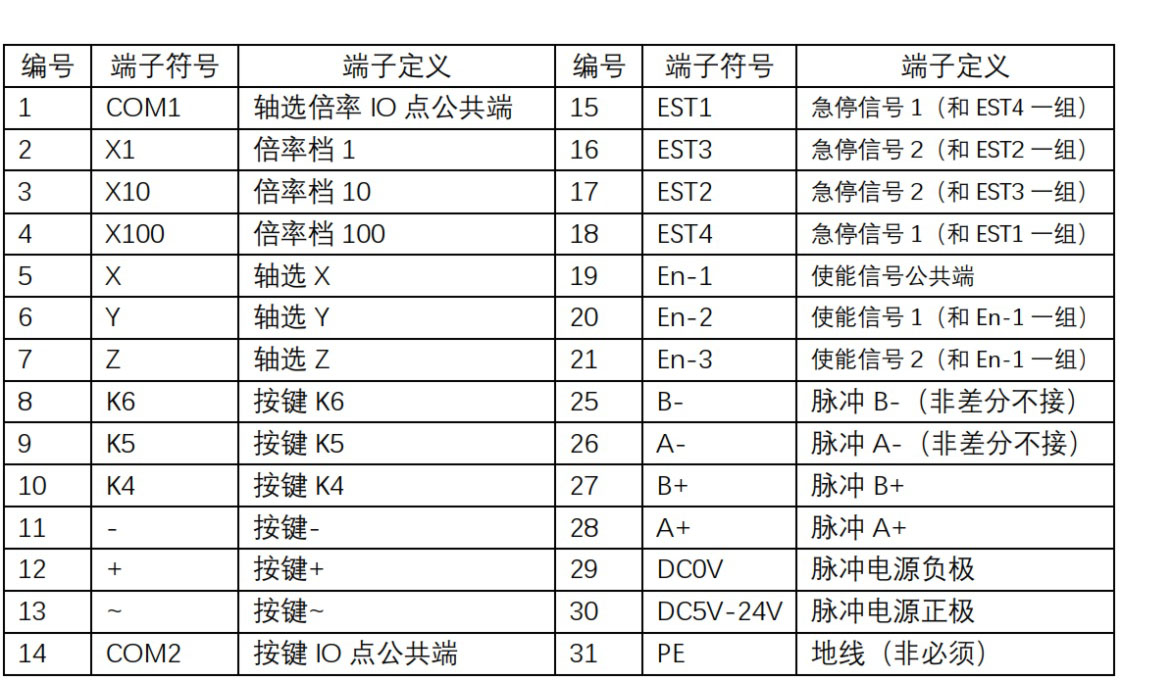

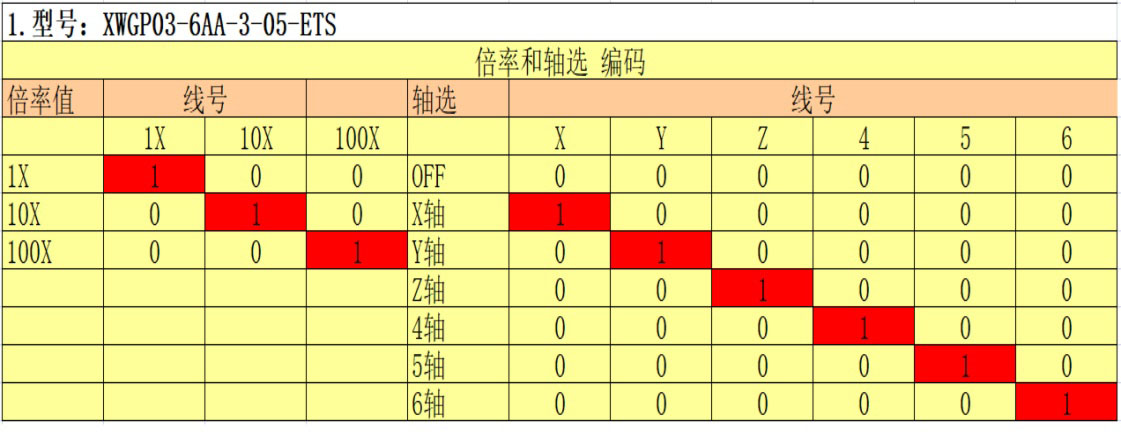

5.Receiver terminal definition and coding table

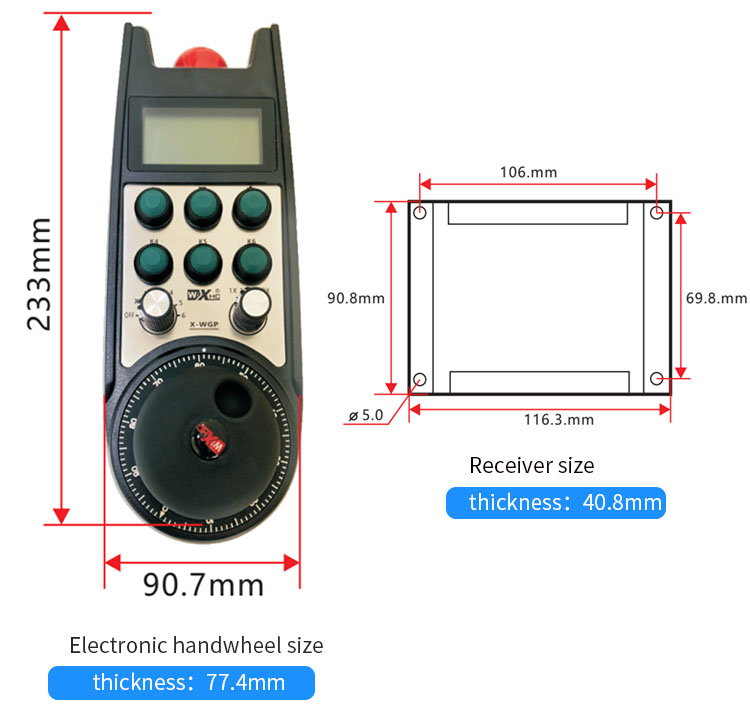

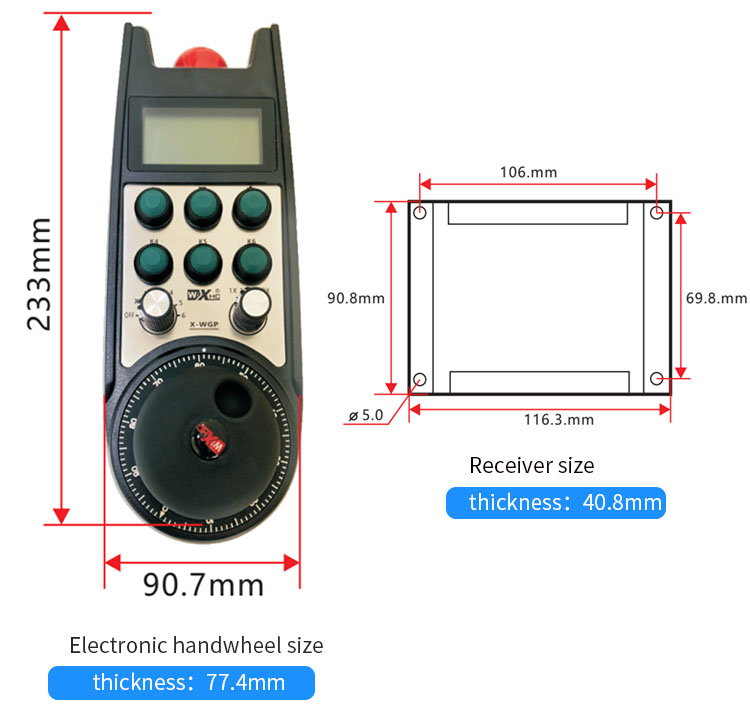

6.Appearance size