Beskrivelse

1.Produkt introduksjon

Trådløst elektronisk håndratt brukes til manuell veiledning, posisjonering, tool setting and

other operations of CNC machine tools. Dette produktet bruker trådløs overføringsteknologi,

eliminerer den tradisjonelle fjærtrådforbindelsen, redusere utstyrsfeil forårsaket av kabler,

eliminating the disadvantages of cable dragging, oil stains, etc., and is more convenient to

operate. It is widely used in CNC machine tools such as gantry machining centers, gantry

vertical lathes, CNC gear processing machines, and can be adapted to a variety of CNC

systems on the market, som Siemens, Mitsubishi, Fanuc, syntec and other CNC system

brands.

2.Produktfunksjoner

1. Ta i bruk 433MHZ trådløs kommunikasjonsteknologi, trådløs operasjonsavstand er 80 meter;

2. Bruk automatisk frekvenshoppingsfunksjon, bruk 32 sets of wireless remote controllers at the

same time without affecting each other;

3. Støtte nødstoppknapp, and after the handwheel is turned off, the emergency stop

button is still valid;

4. Støtte 6 Tilpassede knapper, bryter IO-signalutgang;

5. Støtte 6-akse kontroll, 7-12 aksekontroll kan tilpasses;

6. Støtter 1X,10X, 100X-kontroll og kan maksimalt tilpasses 1000X;

7. Supports the enable button function, output switch l0 sianals. valg av akse,maanification

and encoder.;

8. Support axis selection and magnification selection encoder output;

9. Støtter standard Type-C-lading, 5V-2A ladespesifikasjon, built-in battery specification

14500/1100mAh.

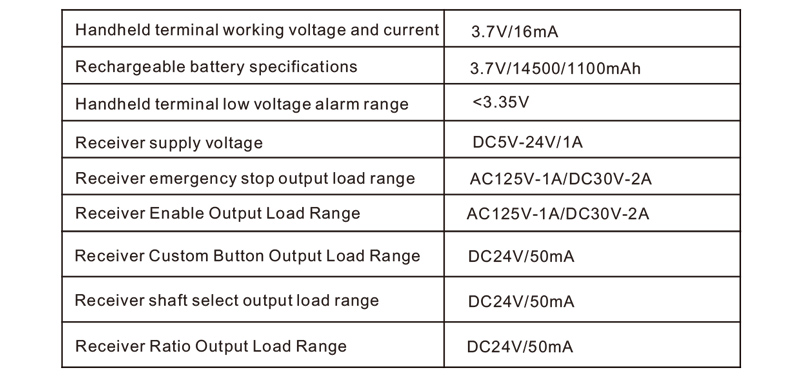

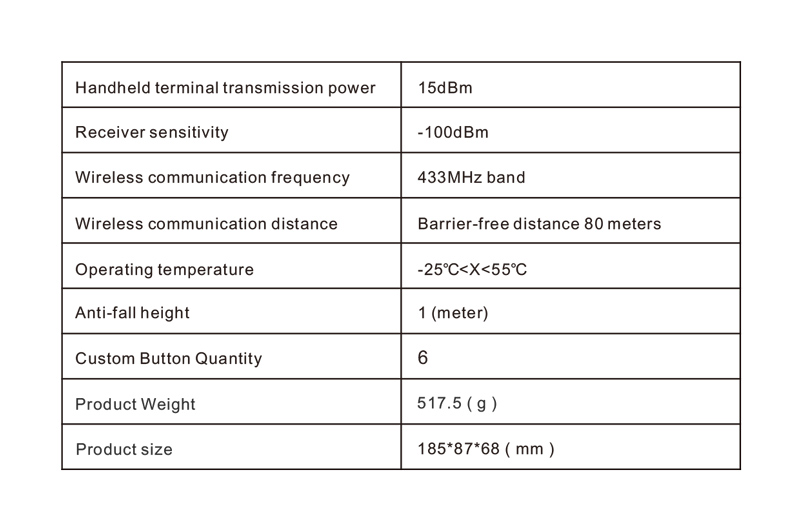

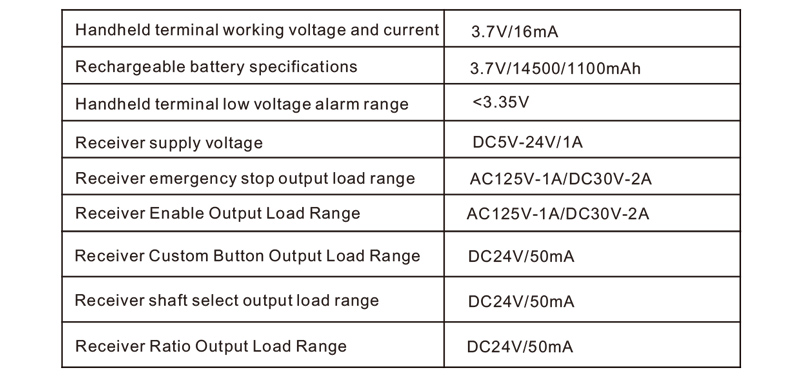

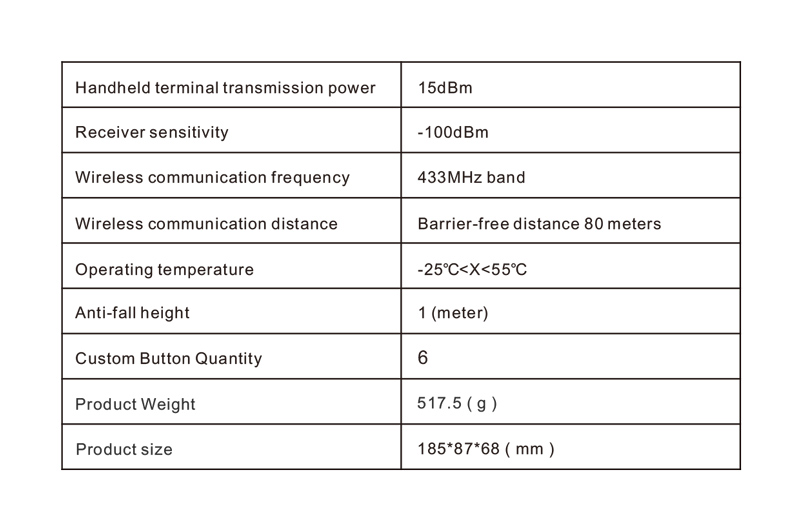

3.Produktspesifikasjoner

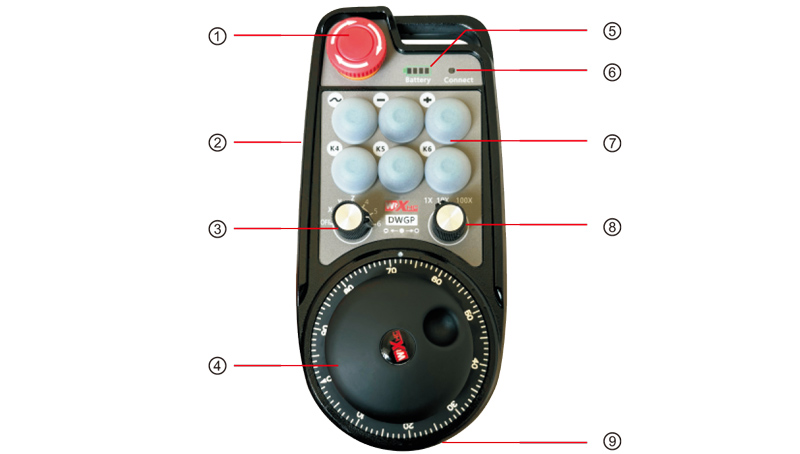

4.Produktfunksjon introduksjon

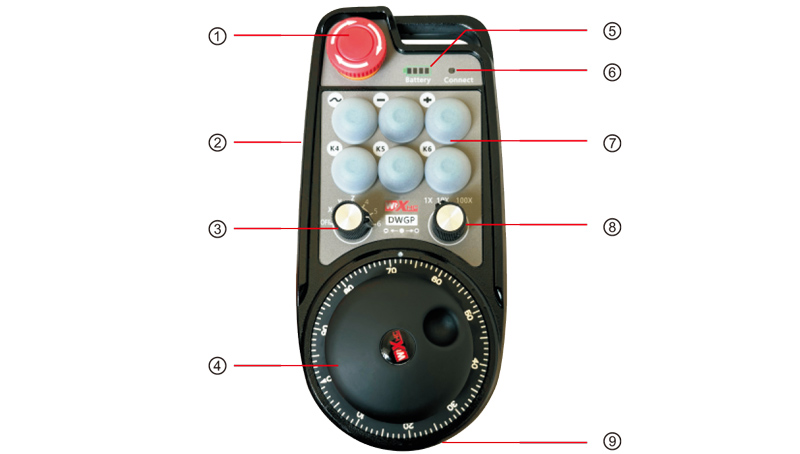

Merknader:

①Nødstoppknapp:

Når nødstoppknappen trykkes, the two emergency stop IO outputs on

the receiver are disconnected, and all handwheel functions are invalid. When the emergency

stop is released, nødstopp IO-utgangen på mottakeren er lukket, and all handwheel

functions are restored; and after the handwheel is turned off, the emergency stop IO output

of the receiver is still valid when the emergency stop button is pressed.

②Enable button:

Press any one of the enable buttons on both sides, and the two groups of enable IO

outputs on the receiver will be turned on. Release the enable button and the enable IO

output will be turned off. I tillegg, you need to press and hold the enable button before

switching the axis selection ratio and shaking the handwheel. This function can be

canceled through the configuration software.

③Axis selection switch (strømbryter):

Press and hold the enable button and switch the axis selection switch to switch the

moving axis controlled by the handwheel. Switch this switch from OFF to any axis and

turn on the handwheel power.

④Pulse encoder:

Trykk og hold aktiveringsknappen og rist pulsgiveren for å sende ut en puls

signal for å kontrollere bevegelsen til maskinaksen.

⑤Battery indicator:

The hand wheel power display, all bright means full power, all off means it is not

turned on or has no power, the first left grid flashes, indicating that the power is too low,

please charge in time.

⑥Signal Lights:

If the signal light is on, it means the handwheel is being operated and the signal is

normal; if the signal light is off, it means there is no operation, or it is being operated but

the wireless signal is not connected.

5.Produkttilbehør Diagram

6.Produktinstallasjonsveiledning

6.1 Produktinstallasjonstrinn

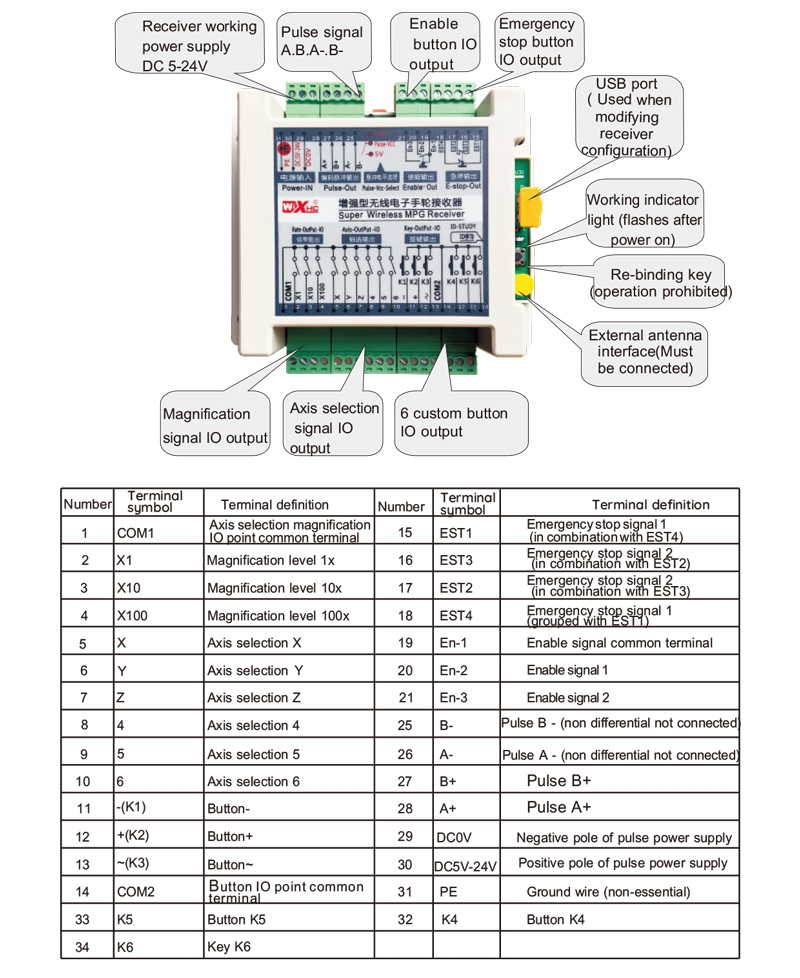

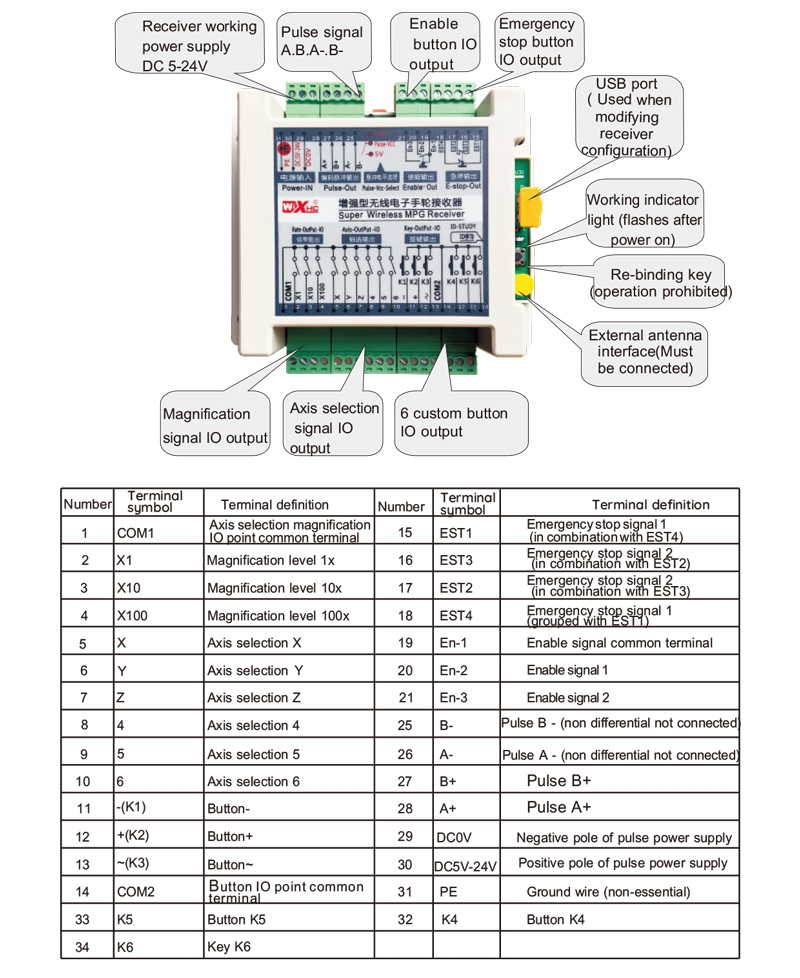

1. Install the receiver in the electrical cabinet using the clips on the back, or install it in

the electrical cabinet using the screw holes at the four corners of the receiver.

2.Se vårt koblingsskjema for mottakeren, sammenligne det med utstyret ditt på stedet, og koble til

utstyret til mottakeren via kabler.

3.Etter at mottakeren er fikset, antennen utstyrt med mottakeren må være tilkoblet,

og den ytre enden av antennen må installeres eller plasseres utenfor det elektriske skapet. Den

is recommended to place it on the top of the electrical cabinet for the best signal effect. It is

forbidden to leave the antenna unconnected or place the antenna inside the electrical cabinet,

som kan føre til at signalet blir ubrukelig.

4. Endelig, slå på håndhjulets strømbryter og du kan betjene maskinen ved å

håndratt fjernkontroll.

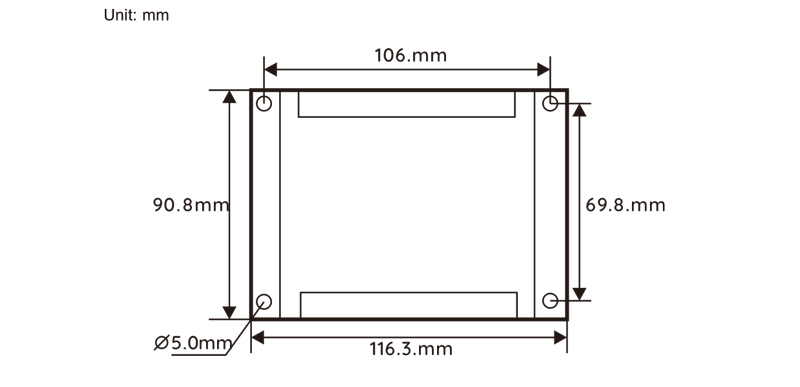

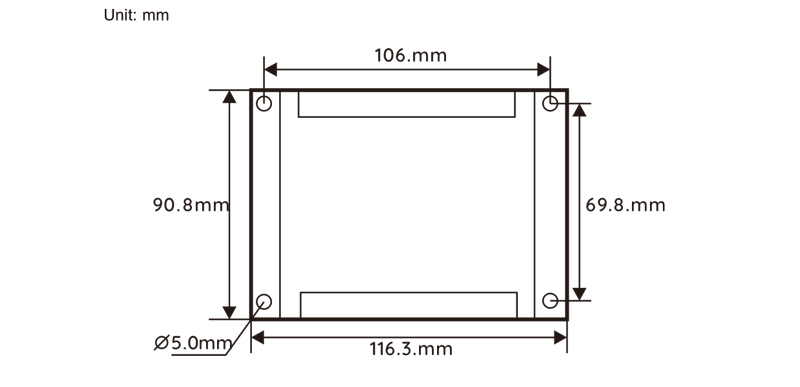

6.2 Mottakerinstallasjonsdimensjoner

6.3 Mottaker Kabling Referansediagram

7.Produktdriftsinstruksjoner

1. The machine is powered on, the receiver is powered on, the receiver working indicator

light flashes, the wireless electronic handwheel has the battery installed, the battery cover

is fastened, the wireless electronic handwheel power switch is turned on, og den

handwheel power light is on;

2. Velg koordinataksen: Trykk og hold inne aktiveringsknappen, switch the axis selection

bryter, and select the axis you want to operate on;

3. Velg forstørrelse: Trykk og hold inne aktiveringsknappen, switch the magnification switch,

and select the magnification level you need;

4. Bevegelig akse: Trykk og hold inne aktiveringsknappen, velg bryteren for aksevalg, velge

the magnification switch, and then rotatethe pulse encoder to rotate the positive moving axis

clockwise and the negative moving axis counterclockwise;

5. Trykk og hold en egendefinert knapp, and the corresponding button IO output of the

receiver will be turned on. Release the button to turn off the output;

6. Trykk på nødstoppknappen, the corresponding emergency stop IO output of the

receiver is disconnected, the handwheel function is disabled, release the emergency stop

button, the emergency stop IO output is closed, and the handwheel function is restored;

7. Hvis håndhjulet ikke betjenes over en periode, it will automatically enter sleep

mode to reduce power consumption. Når den brukes igjen, the handwheel can be

activated by pressing the enable button;

8. Hvis håndhjulet ikke brukes over lengre tid,it is recommended to switch the handwheel

shaft to the OFF position, slå av håndhjulet, og forlenge batterilevetiden.

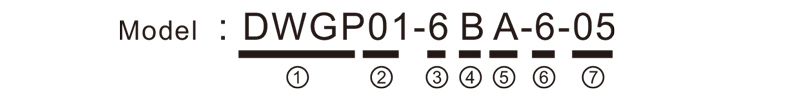

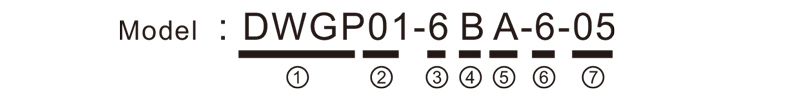

8.Produktmodellbeskrivelse

① :DWGP represents the appearance style

② :Pulsutgangsparametere:

01: Indicates that the pulse output signals are A and B, and the pulse voltage is 5V; Pulse

quantity 100PPR;

02: Indicates that the pulse output signals are A and B, and the pulse voltage is 12V; Pulse

quantity 25PPR;

03: Indicates that the pulse output signal is A B、A-、B-; Pulsspenning 5V; Pulse quantity 1

00PPR;

04: Indikerer en lav-nivå NPN åpen kretsutgang, med pulsutgangssignaler på A og B; de

number of pulses is 100PPR;05: Indikerer høynivå PNP-kildeutgang, pulse output signals

are A and B; pulse quantity is 100PPR;

③ : representerer antall aksevalgbrytere, 6 representerer 6 akser, 7 representerer 7 akser.

④ : represents the type of axis selection switch signal, A representerer punkt-til-punkt utgangssignal,

B represents encoded output signal;

⑤ : represents the type of magnification switch signal,

A representerer punkt-til-punkt utgangssignal, B represents encoded output signal;

⑥ : represents the number of custom buttons, 6 representerer 6 Tilpassede knapper;

⑦ : represents the power supply for the system handwheel, 05 representerer 5V strømforsyning,

og 24 represents 24V power supply.

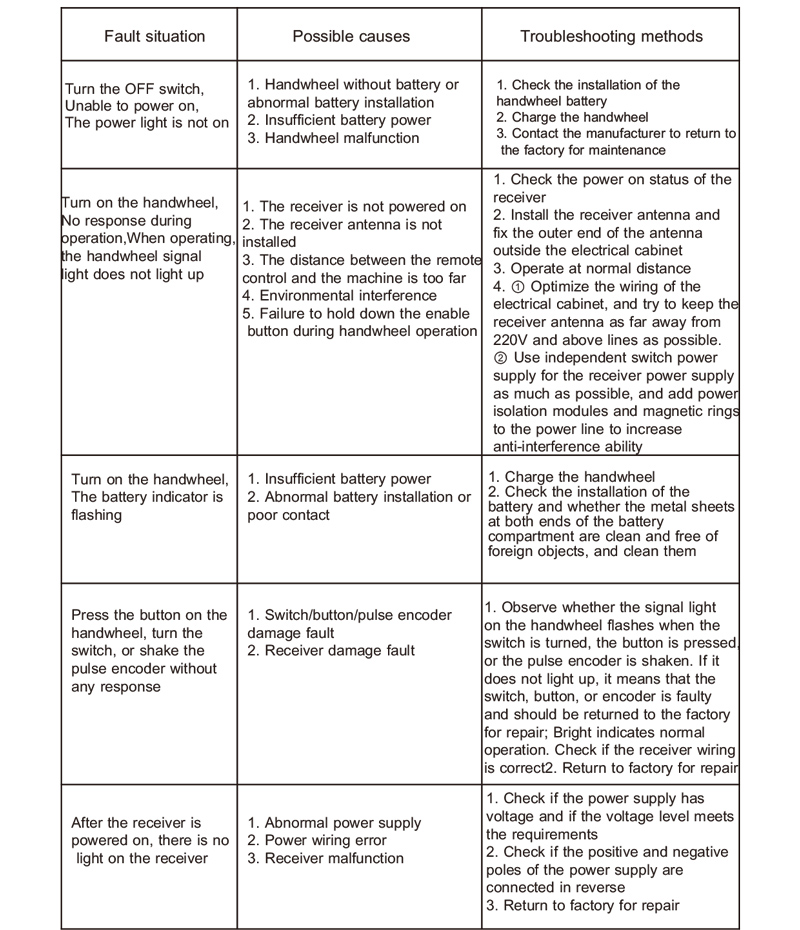

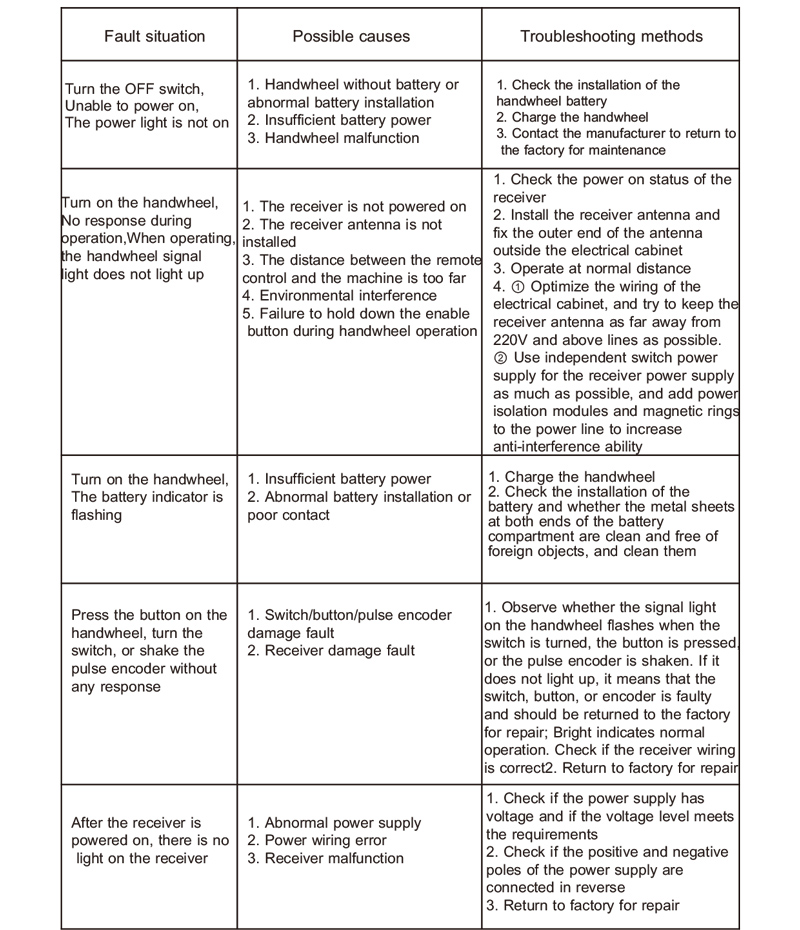

9.Feilsøking av produktet

10. Vedlikehold og stell

1. Bruk den i et tørt miljø ved romtemperatur og trykk for å forlenge levetiden;

2. Unngå å bruke i unormale miljøer som regn- og vannbobler for å forlenge levetiden;

3. Hold håndhjulets utseende rent for å forlenge levetiden;

4. Vennligst unngå å klemme, fallende, støtende, osv. to prevent damage to the precision components inside

the handwheel or accuracy errors;

5. Hvis ikke brukt i lang tid, oppbevar håndhjulet på et rent og trygt sted;

6.Under lagring og transport, oppmerksomhet bør rettes mot fuktighet og sjokkmotstand.

11.Sikkerhetsinformasjon

1. Les instruksjonene nøye før bruk og forby ikke -fagpersoner å drifte;

2. When the battery level is too low, please charge it in time to avoid errors caused by insufficient

battery and inability to operate the handwheel;

3. Hvis reparasjon er påkrevd, Ta kontakt med produsenten. Hvis skaden er forårsaket av selvreparasjon, produsenten vil ikke gi garanti.