Keterangan

1. Pengenalan Produk

The remote control for automatic cutting of track car rope saw is suitable for track type rope saw

cutting machines. It uses the 485 Modbus RTU protocol to control the left and right track frequency

converters, as well as the large motor frequency conversion speed control start and the front, rear,

left and right direction controllers. And it can read the working current of the large motor frequency

converter through the 485 Modbus RTU protocol. By analyzing and comparing the current of the

large motor, the speed of the left and right tracks can be automatically adjusted in real time to

achieve automatic cutting function.

2. Fitur fungsional produk

1. Adopting 433MHz wireless communication technology, dengan jarak pengoperasian nirkabel 100 meter.

2. Mengadopsi fungsi dan penggunaan lompatan frekuensi otomatis 32 sets of wireless remote controllers

simultaneously, tanpa saling mempengaruhi.

3. Supports all frequency converters with 485 Modbus RTU protocol, and currently compatible frequency

converter brands include:Shanghai Xielin, Fuji, Huichuan, Zhongchen, INVT, Dan . For brands

that are not compatible, please contact us for customization.

4. Mendukung pengaturan kecepatan, memulai, dan pembacaan arus konverter frekuensi motor besar.

5. Mendukung pengaturan kecepatan konverter frekuensi jalur kiri dan kanan, memulai, depan, kembali, kontrol kiri dan kanan.

6. Support linear correction of left and right track frequency converters to keep the machine walking in a

straight line.

7. Support automatic cutting function of rope saw, automatically adjust the left and right track speed in

real time according to the current information of the large motor.

8. It is also compatible with direct IO output control for motor start and stop, and analog voltage output

control for motor speed.

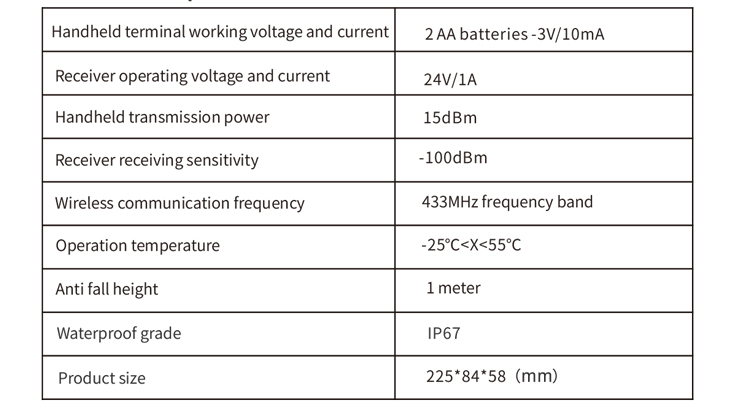

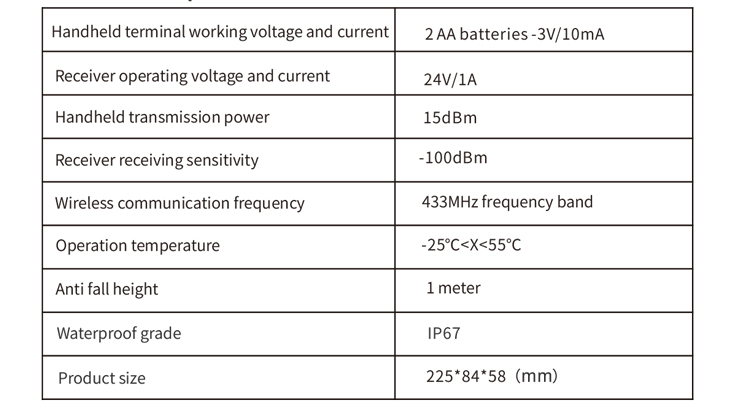

3. Spesifikasi produk

4. Pengenalan Fungsi Produk

Catatan:

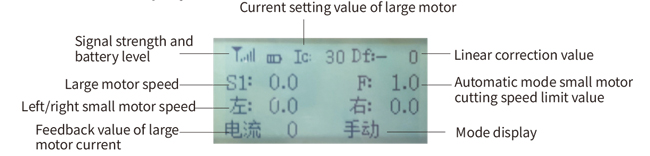

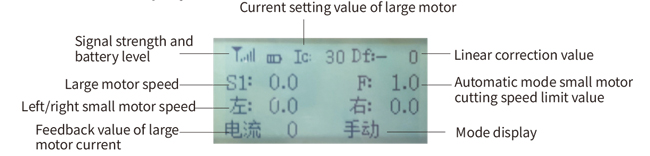

①Screen display:

②Mode switch:

③Enable:

Combination buttons, some operations require holding down the enable button for operation,see the instructions for each switch for details.

④Large motor switch:

Using a 3-speed reset switch, pulling this switch can control the forward and reverse rotation of the large motor. Setelah melepaskannya, the state will remain, and there will be corresponding displays on the screen. The S1↑ arrow indicates forward rotation, and the S1 ↓ arrow indicates everse rotation.

⑤Small motor forward/reverse switch:

The small motor is equipped with a 3-speed self-locking switch in front of it. Pressing the enable button and pulling this switch can control the small motor to move forward and backward, and the corresponding display will appear on the screen.The ↑↑ arrow represents forward, and the ↓↓ arrow represents backward.

⑥ Straight line correction:

Using a multi turn encoder knob, press the enable button, turn the knob right, and display the straight line correction: Df: The left turn knob increases by 1 unit per rotation, and the left

motor speed increases by 0.1 unit; Turn left knob, straight line correction display: Df: On the right, every turn of the knob increases by 1 unit, and the speed of the right motor increases

by 0.1 unit.

⑦Small motor turning switch:

Using a 3-speed reset switch, when manually operated, the small motor can be controlled to turn left or right. Once released, the remote control will automatically stop this action. In the forward state, when this switch is turned, the corresponding display will appear on the screen. The ←↑ arrow indicates left turn, and the ↑→ arrow indicates right turn.When in reverse mode, turn this switch and the corresponding display will appear on the screen. The ←↓ arrow indicates left turn, and the ↓→ arrow indicates right turn.

⑧ Large motor speed regulation:

Using a multi turn encoder knob, rotating 1 grid each time, the speed value of the large motor changes by approximately 0.2 units. Fast rotation can quickly modify the speed value of the large motor.

⑨ Small motor speed regulation:

Using a multi turn encoder knob, in manual mode, press the enable button and then rotate one grid at a time,the speed value of the left and right small motors changes by about 0.1 units, and quick rotation can quickly modify the speed value of the small motor.In automatic mode, press the enable button and rotate one grid at a time,the speed limit value F of the small motor changes by approximately 0.1 units. Rapid rotation can quickly modify the speed limit value of the small motor.

⑩ Remote control power switch

The remote control display screen is turned on.

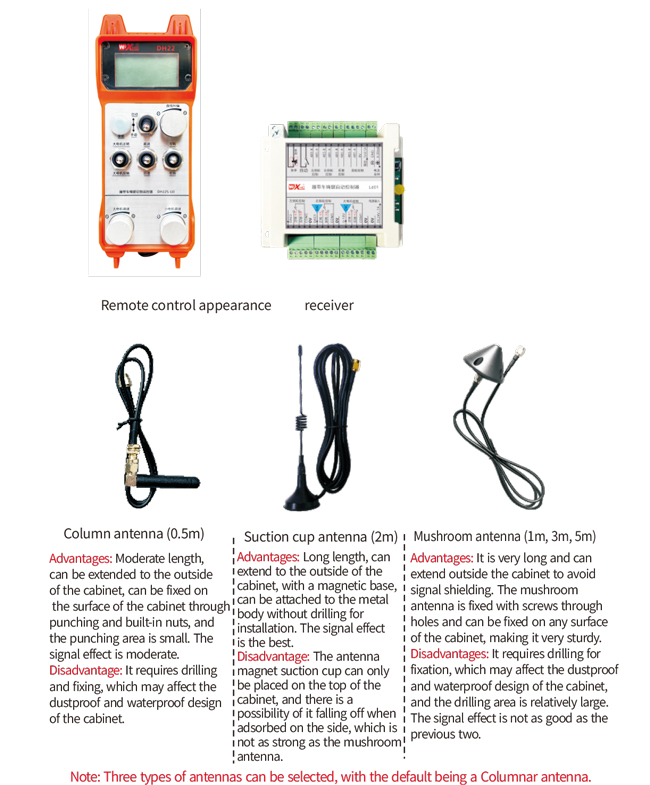

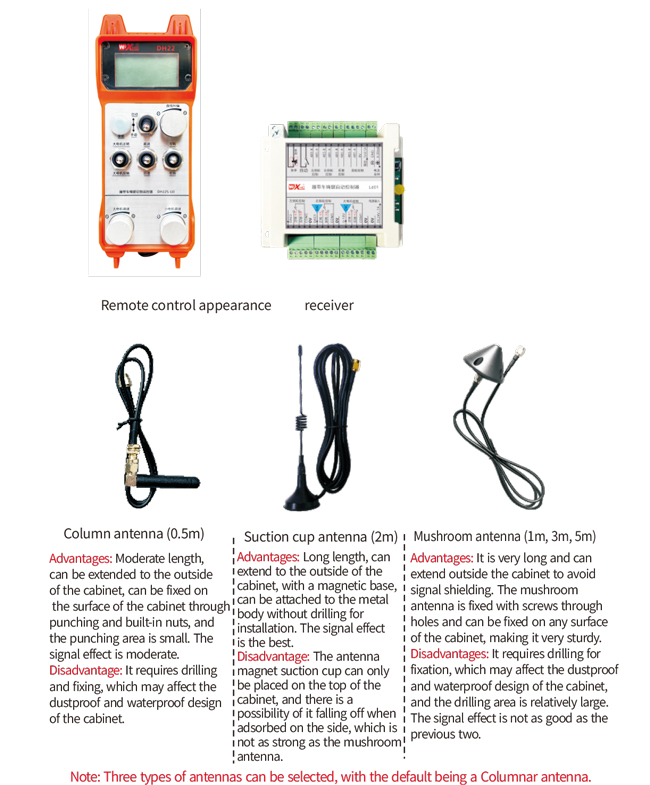

5. Diagram aksesori produk

6. Panduan Instalasi Produk

6.1 Langkah-langkah instalasi produk

1. Pasang penerima ke dalam kabinet listrik melalui gesper di bagian belakang, atau pasang ke dalam kabinet melalui lubang sekrup di keempat sudut penerima.

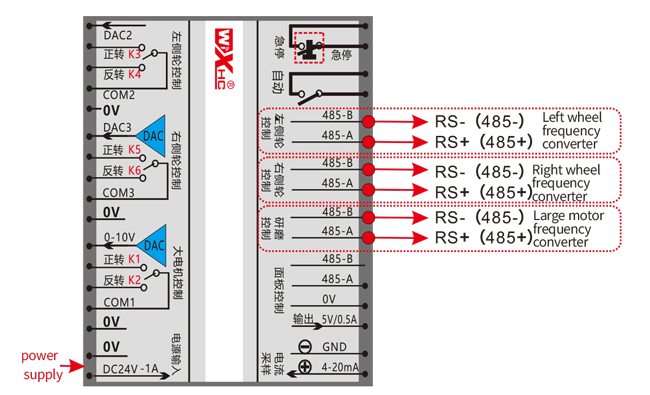

2. Lihat diagram pengkabelan receiver kami dan bandingkan dengan peralatan di lokasi Anda. Connect the equipment to the receiver through wires.

3. After fixing the receiver, it is necessary to connect the antenna equipped with the receiver and install or place the outer end of the antenna outside the electrical cabinet. Disarankan untuk meletakkannya di bagian atas kabinet listrik untuk efek sinyal terbaik. It is forbidden to leave the antenna unconnected or place it inside the electrical cabinet, as it may cause the signal to be unusable.

4. Akhirnya, install the battery on the remote control, tighten the battery cover, and turn on the power switch of the remote control. After the remote control display screen shows the normal

working interface, remote control operations can be performed.

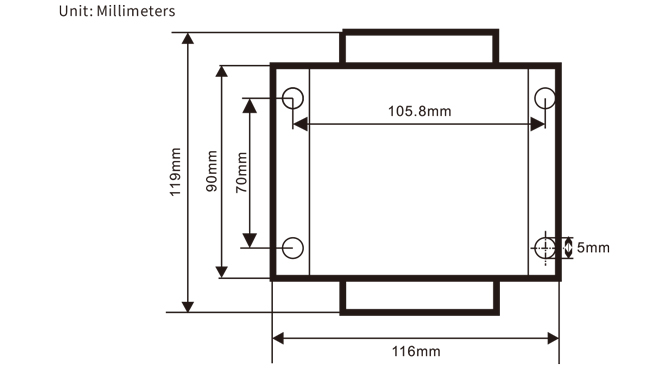

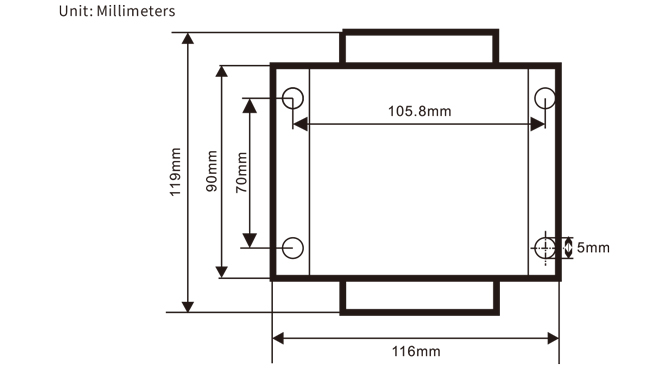

6.2 Dimensi pemasangan penerima

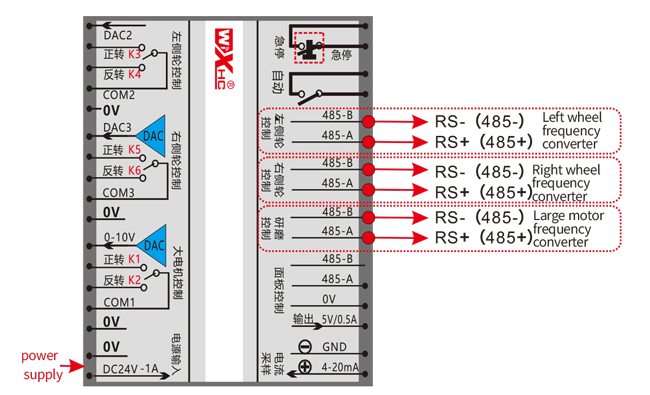

6.3 Diagram Referensi Pengkabelan Penerima

7. Petunjuk pengoperasian produk

7.1 Remote Control Parameter Settings

Method to enter the remote control backend parameters:

Turn the mode switch to manual mode, adjust the speed of the small motor to 25 on both sides, or 0, 10, 20, 40, 50 on all sides, and continuously turn the forward switch of the large motor up 3 times and down 3 times;

Use the “Small Motor Speed Control” knob to flip pages, press the enable button, and then turn the small motor speed control knob to modify parameters. After modification, turn the page to the end,select “Save” to exit, and press the enable button to exit the menu;

The parameters are as follows:

Maximum current: feedback range of large motor current, set range 15-200A, default 100;

Speed control parameters: Automatic mode, small motor automatically accelerates faster or slower,the smaller the faster, set range 200-1500, default 800;

Deceleration parameter: Set the upper limit that allows the motor speed to change. When the current changes beyond this value, the deceleration will occur. The smaller, the faster the deceleration of the left and right motors, dengan berbagai 05-12 and a default of 06;

Acceleration a1: The larger the motor speed, the faster it increases, dengan berbagai 00-06 and a default of 01;

Deceleration a2: The larger the motor speed, the faster it decreases, dengan berbagai 00-06 and a default of 02;

Enable speed regulation: Does the small motor speed regulation need to be enabled? 00 does not enable, 01 enables, default is 01;

Start self-locking: Does the large motor automatically maintain self-locking after the forward and reverse switches are released? 00 does not hold, 01 holds, default 01

Maximum walking: maximum speed of left and right motors, range 10-100, default 50;

Cutting current: maximum cutting current, displayed on the screen as IC value, range 15-160, default 30,

corresponding to IC: 30 displayed on the screen. The upper limit of this parameter is 80% of the maximum current;

Default speed limit: The default small motor automatic cutting speed when turned on is within the range of 0-100, with a default of 10. The screen displays F1.0, and this parameter is only accurate when the maximum walking is set to 50.

Automatic mode: Set to 00, the automatic/manual switch is a mode switch. Set to 01, the automatic/manual switch is set to the automatic position, the display screen shows lighting, and the automatic terminal output on the receiver is closed. When set to manual, the automatic output terminal is disconnected;

Speed limit deviation: The upper limit of the automatic cutting speed of the small motor ranges from 00 ke 200, with a default of 60 and a corresponding display of 6.0 on the screen; Upper limit of display value=speed limit offset x 0.1;

Maximum host: maximum speed of the large motor, range 10-100, default 50;

Mbus equipment (mandatory): Selection of large motor frequency converter model, range 00-03, default 03;

00- Shanghai Xielin 01-Fuji

02-INVT 03-Inovance(Zhongchen, Robicon)

SBUS equipment (mandatory): Small motor frequency converter model selection, range 00-05, default 03;

00- Shanghai Xielin 01-Fuji

02-INVT 03-Inovance(Zhongchen, Robicon)

04-Anchuanda 05-None

7.2 Parameter setting of frequency converter

1. Command source selection: Communication command channel

2. Main frequency source selection: communication given

3. Baud rate: 19200

4. Data format: No verification, data format<8-N-1>

5. Local address: Set the left frequency converter to 1, the right frequency converter to 2, Dan

the large motor frequency converter to 3

7.3 Remote Control Operation Instructions

1. Power on the machine, nyalakan kendali jarak jauh, enter the remote control backend, set the

remote control backend parameters, mainly setting the small motor and large motor frequency

converter models: (skip this step if the machine manufacturer has already set it);

2. Set the parameters of the frequency converter (skip this step if the machine manufacturer

has already set it);

3. Set the remote control to manual mode, and then use the remote control to move the machine to

the working position;

4. In manual mode, set the cutting current of the large motor to IC and the speed of the large motor

5. Switch to automatic mode and set the cutting speed limit F value for the small motor;

6. In automatic mode, turn the large motor switch to forward to start the large motor, then turn

the small motor switch to forward or reverse, and the remote control enters automatic cutting

mode to start cutting.

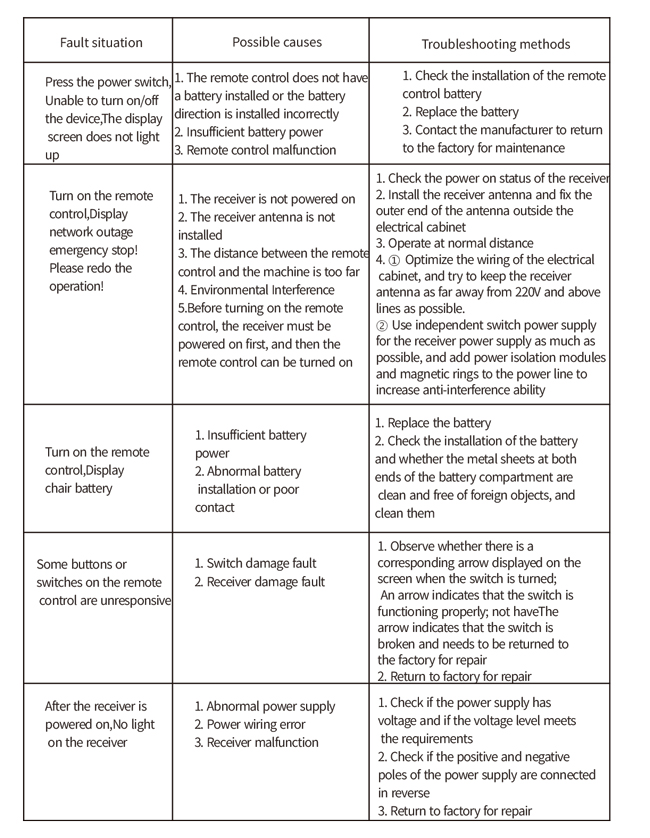

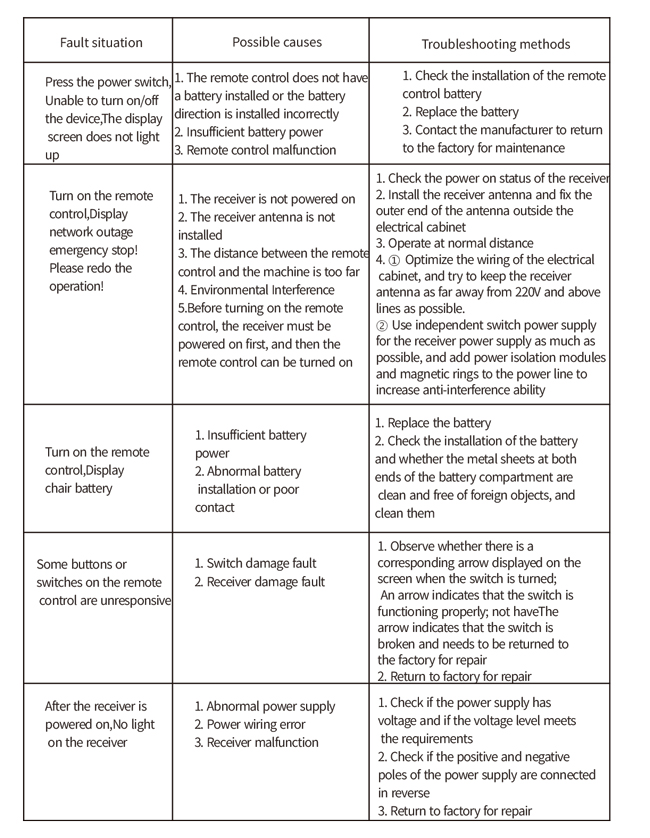

8.Product troubleshooting

9.Maintenance

1. Silakan gunakan di lingkungan kering pada suhu dan tekanan kamar untuk memperpanjang masa pakainya.

2. Harap hindari penggunaan di lingkungan yang tidak normal seperti hujan dan gelembung air untuk memperpanjang masa pakai.

3. Please keep the battery compartment and metal shrapnel area clean.

4. Please avoid damaging the remote control due to squeezing and falling.

5. Jika tidak digunakan dalam waktu lama, please remove the battery and store the remote control and battery in a clean

and safe place.

6.Selama penyimpanan dan transportasi, perhatian harus diberikan pada kelembaban dan ketahanan guncangan.

10. Informasi Keselamatan

1. Harap baca instruksi dengan seksama sebelum digunakan dan melarang non-profesional mengoperasikannya.

2. Please replace the battery in a timely manner when the battery is too low to avoid errors caused by

insufficient power, which may result in the remote control being unable to operate.

3. Jika perbaikan diperlukan, silakan hubungi produsennya. Jika kerusakan disebabkan oleh perbaikan sendiri, the manufacturer

will not provide warranty.