Descriptio

1. Product Introduction

Remotus imperium pro autocineto sectione viae car funiculi serrae aptae est ad tramitem generis funem serratum

machinis cutting. Hoc utitur 485 Modbus RTU protocollum ad moderandum in semita dextra frequentia

converters, itemque magna mobilitas frequentia conversionis celeritatis imperium initium et frontem, tergo,

dextra parte moderatoris. Et legere potest currentem currentem frequentiae motoriae magnae

converter per 485 Modbus RTU protocol. Per hodiernam analyzing et comparet

magna motricium, celeritas dextra vestigia statim adaequatum in reali tempus

consequi automatic munus sectione.

2. Product eget features

1. Inito 433MHz communicationis technologiae wireless, cum wireless operating spatium of * 100 metris.

2. Accipere automatico frequency circumsiliens munus et usum 32 ponit wireless remotis moderatoris

simul, Sine se afficiens se.

3. Sustinet omnem frequency converters cum 485 Modbus RTU protocol, et currently, compatible frequency

converter brands includit:Shanghai Xielin, Fuji, Huichuan, Zhongen, Invten, et . Nam brands

quae non compatible, contact us pro customization.

4. Support Celeritas DISCIPIO, satus, et vena Lectio magna motor frequency converters.

5. Support sinistram et dexteram track frequency converter celeritate ordinatione, satus, ante, retrorsum, Reliquit ius potestate.

6. Support linearibus correctione sinistram et dexteram semita frequency convertellis ut machina ambulantes in

linea.

7. Suscipe latae sectionis functionem funem serrae, automatice accommodare ad sinistram et ius track celeritas in

verum tempus secundum ad hodiernam informationem de magna motricium.

8. Compatibile est etiam cum potestate directa IO output pro motore incipiendi et cessandi, et Analog voltage output

imperium ad motricium celeritas.

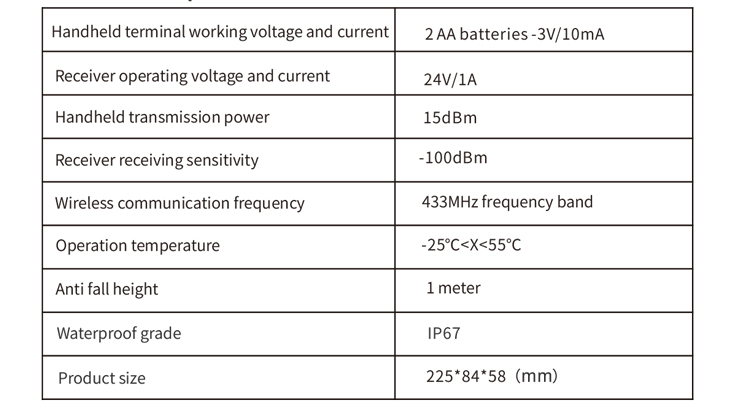

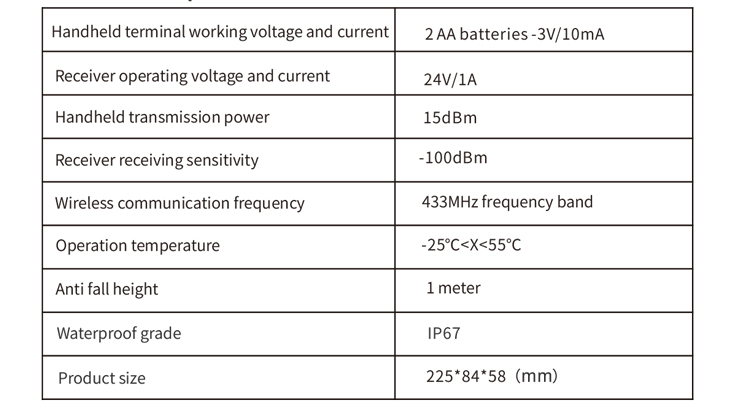

3. Product Specifications

4. Product Function Introduction

Nota:

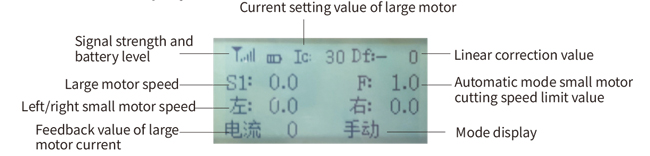

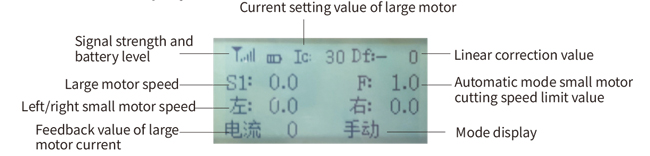

①screen ostentationem:

②mode switch:

-Admitte:

Cuncta Bullae, Quidam operationes requirere tenentes ad enable puga operandi,videte instructiones pro singulis transitum per singula.

Large motricium switch:

Using in III-celeritate reset switch, Tollens hoc switch potest control deinceps et converso gyrationis magna motricium. Post dimittis eam, De re publica remanebit, et ibi erit correspondentes ostendimus in screen. S1 "sagitta gyrationis deinceps indicat", et S1 sagitta indicat semper rotationem.

⑤Small motricium deinceps / Reverse SWITCH:

Parvus motor instructus est 3-celeritate auto-densis switch in conspectu eius. Comprimens conjunctionem enable et hanc transitum trahens parvam motorem progredi et retrorsum regere potest, Et apparebit in screen.The sagitta deinceps repraesentat, et sagitta repraesentet retrorsum.

rectae correctionis:

Using a multi rursus encoder Knob, premet ille enable button, convertat nodi recta, et rectam correctionem: DF: Sinistra vertente nodum augetur per 1 unitas per gyrationis, et ad sinistram

motricium celeritas augetur 0.1 unitas; Turn sinistram Knob, recta disciplinam display: DF: Ad dextram, singulis nodi augetur 1 unitas, et celeritate motoris recti augetur

by 0.1 unitas.

Parvus motricium conversionis switch:

Using in III-celeritate reset switch, Cum manually operated, Parva motricium potest regi ad dextram sinistram vel. Semel dimisit, remota potestate mos automatically prohibere hoc opus. In deinceps status, Cum hoc switch est, congruum spectaculum apparebit in tentoriis. Sagitta indicat et rursus ad sinistram, et → sagitta indicat ius turn.When in principio modus, Hoc apparebit switch et secundum propono in screen. Sagitta indicat et rursus ad sinistram, et → sagitta indicat dextram rursus.

⑧ magna motor celeritate ordinacione:

Using a multi rursus encoder Knob, rotating 1 eget omni tempore, Celeritas valorem de magna motor mutationes per circiter 0.2 unitates. Celeriter gyrationis celeritas valorem celeritatis motoris magni mutare potest.

Parvus celeritas motricium ordinatio:

Using a multi rursus encoder Knob, In manual modus, premere possint felis et gyrari unum malesuada tempus,celeritas valorem sinistra ac dextra parva motorum mutatur per circuitum 0.1 unitates, et gyratio velox potest celeriter mutare valorem celeritatis parvi motoris.In ipso modo, premere possint felis ac gyrari unum malesuada tempus,celeritas terminus valorem F parvae mutationes motoris circa 0.1 unitates. Celeri gyrationis celeritas terminum celeritatis mobilis parvi momenti mutare potest.

Longinquus imperium potentiae switch

Remote control ostentationem screen est in.

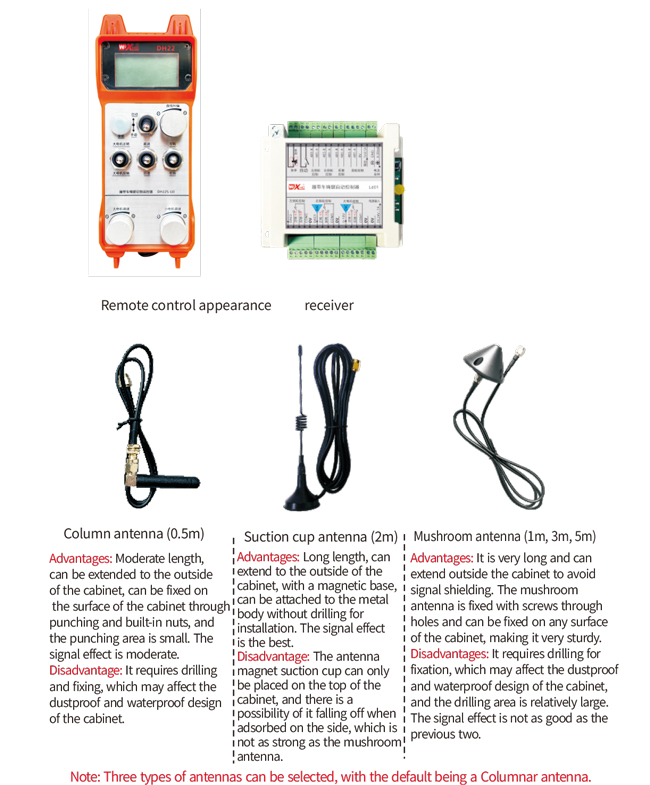

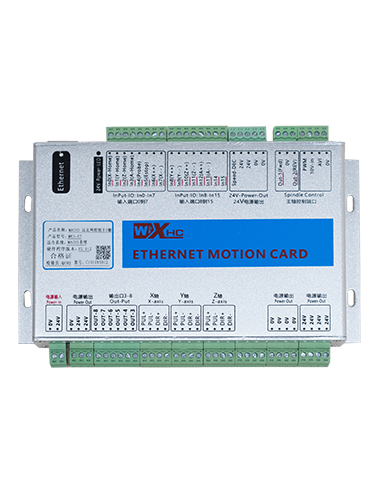

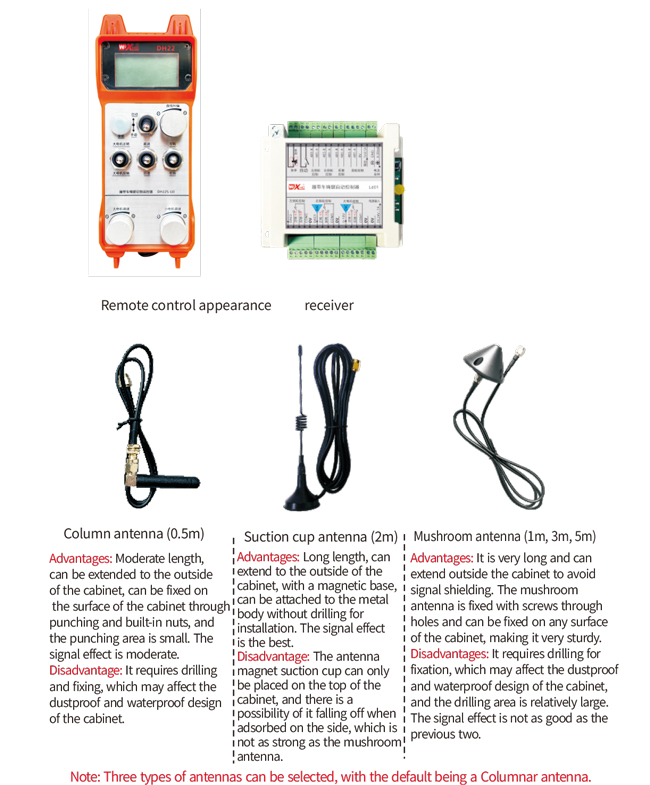

5. Product Accessory Diagram

6. Product institutionem dux

6.1 Installation gradus productum

1. Install receptaculum in electricum scrinium per fibula a tergo, vel in scrinium per cochleam in quattuor angulis recipientis niteremur eam.

2. Recipe ad acceptorem wiring diagram et compara cum apparatu tuo on-site. Coniungere apparatu ad accipienti per fila.

3. Post taxationem accipit, necesse est antennas cum receptatore coniungere instructas et antennas extra electricum arcae electrica instituere vel collocare extremum extremum.. Commendatur ponere super summitatem electrica scrinium optimum signum. Prohibetur antennas disiunctas vel intra electricum scrinium relinquere, ut faciat signum inutile.

4. Tandem, install a remotis imperium in altilium, obstringere altilium operimentum, et conversus in potentia switch ad remotis imperium. Post imperium remotum propono screen ostendit normalem

opus interface, remota potestate operationes peragi possunt.

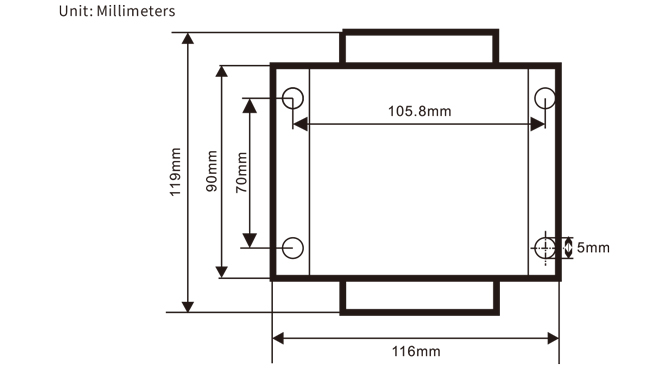

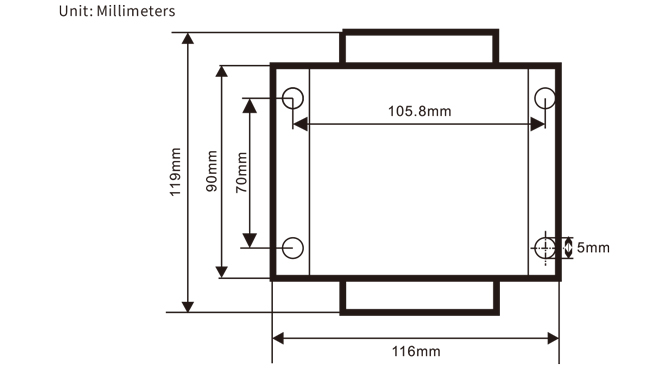

6.2 Receptor installation dimensiones

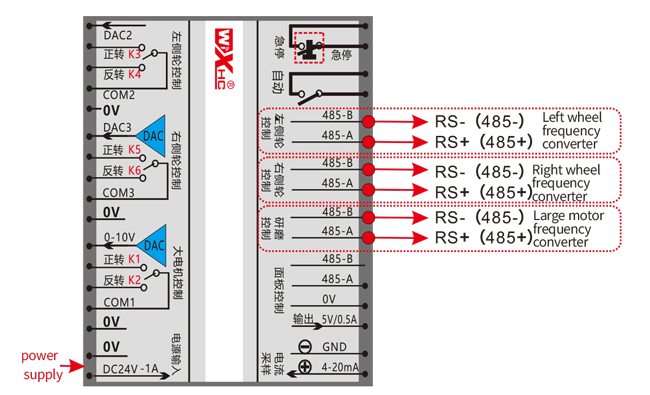

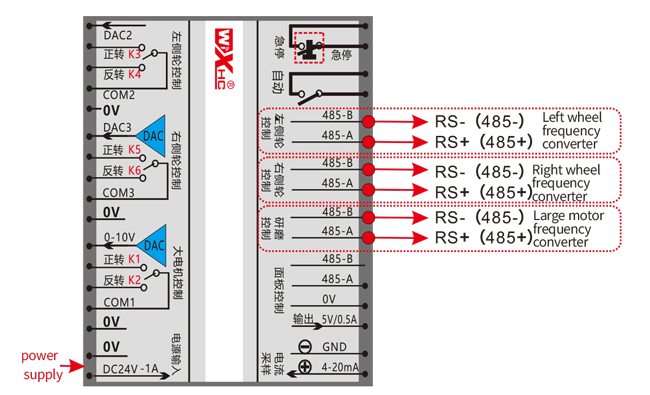

6.3 Receptor Wiring reference Diagram

7. Product Operatio Instructions

7.1 Longinquus imperium parametri occasus

Methodus remota potestate ingrediendi parametri backend:

Convertat modus switch ad manual modus, adjust celeritas parva motricium ad 25 utrimque, vel 0, 10, 20, 40, 50 undique, et continue deinceps transitum magnae motor sursum 3 temporibus deorsum 3 temporum;

Usura “Parvus motor celeritate imperium” nodum ut flip paginis, premet ille enable button, et vertere parva velocitate motricium nodi moderari imperium parametri. Post modificationem, Turn pagina ad finem,selego “Servare” exire, et premere enable puga exire in menu;

Et parametri sunt ut sequitur:

Maximus current: feedback range magnarum motricium current, set range 15-200A, default 100;

Celeritate imperium parametri: Lorem modus, parva motricium sponte accelerat citius vel tardius,et minor citius, set range 200-1500, default 800;

Torus parameter: Constitue autem evolvimus, qui motricium celeritatem mutationem concedit. Cum hodiernam mutationes ultra hanc valorem, retardatio erit. Minora, velocior retardatus dextra motorum, et range 05-12 et defaltam 06;

Acceleratio A1: Maior celeritas motricium, citius augetur, et range 00-06 et defaltam 01;

A2 torpet: Maior celeritas motricium, quo citius decrescat, et range 00-06 et defaltam 02;

Admitte celeritate ordinatione: Non parva regula motoris celeritatis opus esse possit? 00 non enable, 01 dat, default est 01;

Satus auto-densis: An magna motoris sui sponte conservare densis post antrorsum et vicissim virgas emittuntur? 00 non tenet, 01 tenet, default 01

Maximum ambulans: celeritatem maximam dextra motorum, range 10-100, default 50;

Cutting: maxime sectione current, proponendum in screen ut IC valorem, range 15-160, default 30,

correspondentes IC *: 30 in screen proponendum. Evolvimus huius moduli est 80% ad maximum current;

Default celeritas terminum: Defectus parvae motoris automatic secans celeritatem versa est intra teli 0-100, cum defaltam 10. In screen ostendit F1.0, et hic modulus tantum accurate ponitur cum maximus ambulatio 50.

Lorem modus: Set to 00, automatic / switch manual modus est switch. Set to 01, automatic / manual switch est profectus in ipso situ, ostentationem elit ostendit lucendi, et automatic terminatio output in recipiente clauditur. Cum paro ut manual, automatic output terminatio hians;

Celeritas terminus deviationis: Finis superior automatic secans celeritatem parvae motoris iugis e 00 ut 200, cum defaltam 60 ac parem ostentationem 6.0 in screen; Superior modus ostentationis valorem = celeritate terminum offset x * 0.1;

Maximum exercitum: maximam celeritatem ad magnum motricium, range 10-100, default 50;

Mbus armorum (funestus): Electio magnarum motorum frequentiae converter exemplum, range 00-03, default 03;

00- Shanghai Xielin I-Fuji

02-INVT 03-Inovance(Zhongchen, Robicon)

SBUS Equipment (funestus): Motor frequency converter exemplar electio, range 00-05, default 03;

00- Shanghai Xielin I-Fuji

02-INVT 03-Inovance(Zhongchen, Robicon)

04-Anchuananda V-Nihil

7.2 Parameter occasum frequency converter

1. Imperii Source Electio: Communicationis Mand

2. Pelagus frequency Source Electio: communicationis dedit

3. Baud rate: 19200

4. Data Forma: Non verificationem, Data Forma<8-N-I>

5. Loci oratio: Set ad sinistram frequency converter ad 1, ius frequency converter 2, et

magna motricium frequentiam converter to 3

7.3 Remota imperium operationem instructiones

1. Power in machina, Turn in remotis imperium, intrant remota potestate backend, posuit

remote control parametri backend, praecipue parva motoriis magnisque motoriis frequentia

converter exempla: (Skip hoc gradum si machina manufacturer iam posuit eam);

2. Set parametri frequency converter (transiliunt hunc gradum si machina manufacturer

iam profectus est);

3. Constat in remotis imperium manual modus, tum remota potestate movere machinam

operantes locum;

4. In manual modus, pone currentem secantem motoris magni ad IC et velocitatem motoris magni

5. Switch ad Lorem Modus et Set in Cutting celeritate terminum F valore ad parva motricium;

6. In Lorem Modus, Turn magna motor switch ad committitur magna motor, tum vertere

parva motoris transitum in medium seu contra, et remota potestate intrat ipso sectione

modus incipere sectionem.

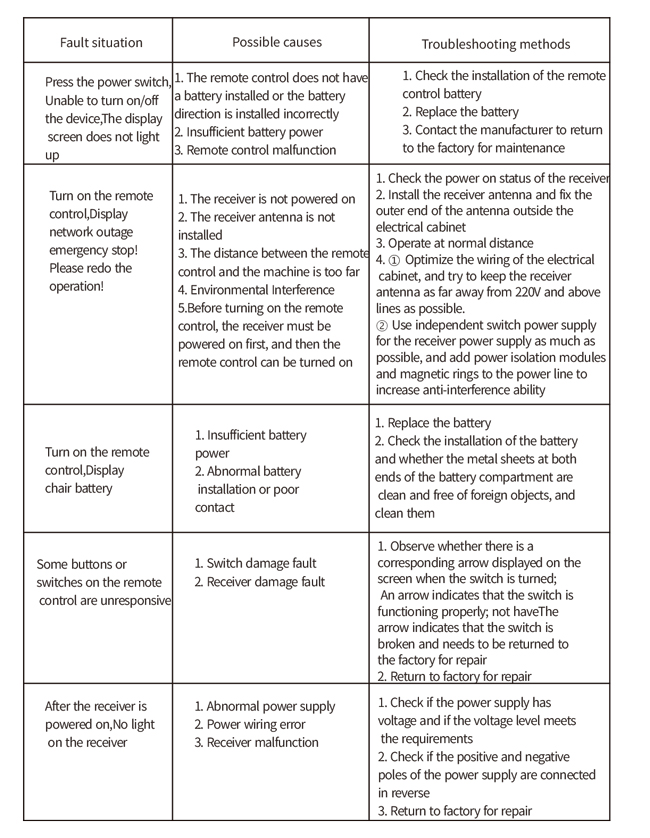

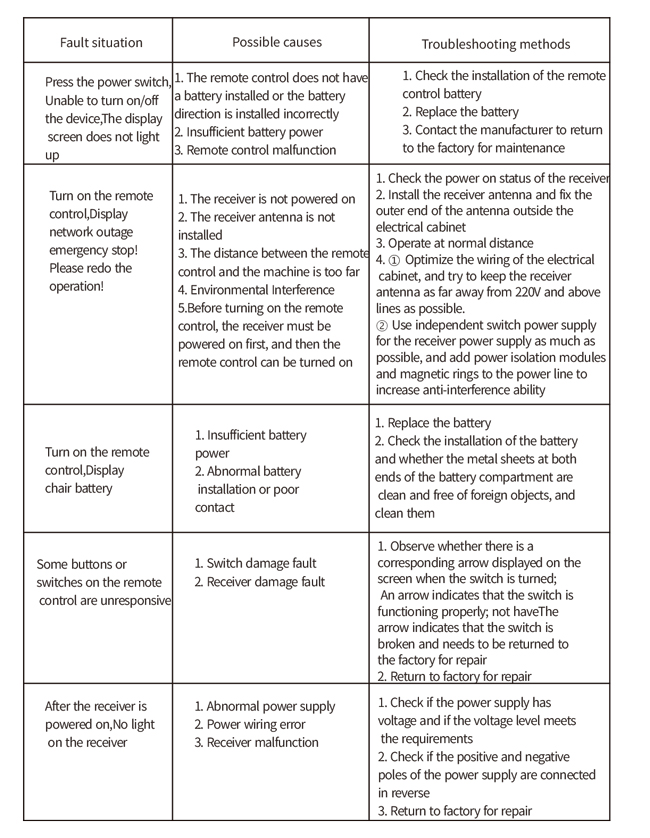

8.Product Troubleshooting

9.Sustentationem

1. Quaeso uti in sicco environment ad locus temperatus et pressura ad extend ad servitium vitae.

2. Quaeso vitare usura in abnormes environments talis pluvia et aqua bullae extendere ministerium vitae.

3. Placere custodiant altilium cellula et metallum shrapnel area mundum.

4. Quaeso vitare damna remote control ob expressa et procidens.

5. Nisi non propter diu, Quaeso remove altilium et reponunt remote imperium et altilium in mundum

et locum tutum.

6.Per repono et translationem, Operam esse solvit ad humorem et inpulsa resistentia.

10. Salus notitia

1. Placere legunt instructiones diligenter ante usum et prohibere non doctorum ex operating.

2. Quaeso reponere opportune pugna modo cum pugna est humilis ad vitandum errores

satis virtutis, quae consequuntur in remotis imperium non operari.

3. Si reficere non requiritur, Placere contact fabrica. Nisi damnum est causa sui reparatione, fabrica

warantum non providere.