Descriptio

1.Introductio remota potestate

a.Product Composition

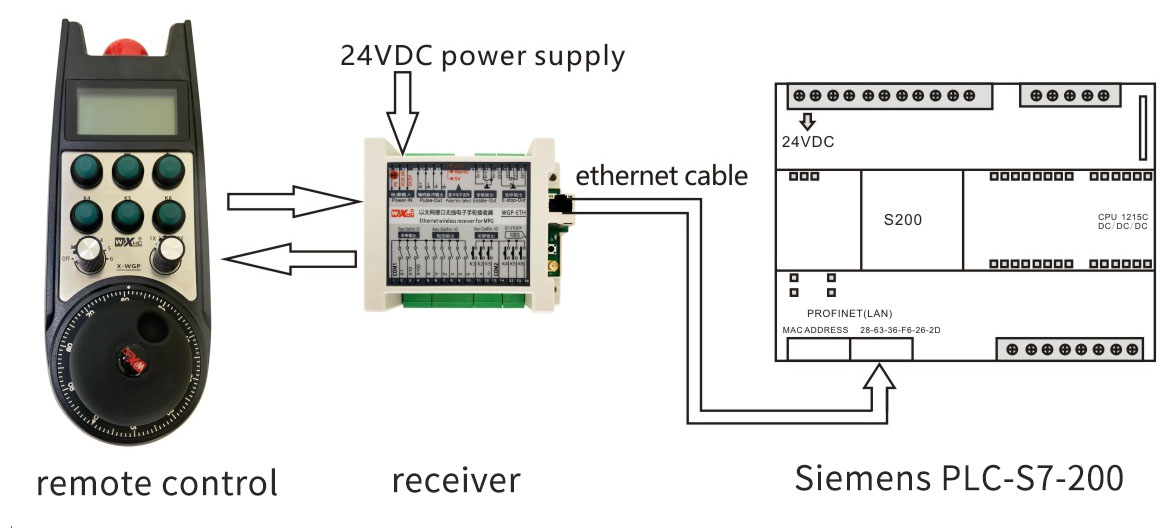

Siemens real-time coordinare propono wireless electronic handwheel ex duabus partibus constat: electronic handwheel + accipientis;

b.Characteristics

*Support Siemens PLC: S7-200 / -300 / -1200;Support realis-vicis ostentationem de Siemens ratio coordinare values;

*In Wireless Transmissus distantia aperta 40 metris, Lorem frequency circumsiliens technology, potest 32 apparatu simul;

*Handwheel electronic powered by 2 AA gravida et plus quam adhiberi potest 30 dies;

*Receptaculum externa antennae ad signum augendae instructum et facile est instituere;

*Electronic handwheel firmamentum: Unum 100PPR encoder 、Unum VI, celeritate axis selectionem switch 、 Unum III, celeritate magnificationis switch;

*Electronic handwheel subsidia 6 Custom Bullae, correspondentes Siemens PLC oratio, Quod potest esse sponte programmed;

*6 Custom Bullae potest control 6 switch outputs;

*Propono screen ostendit PLC correspondentes mandare coordinatum valorem in reale tempus, ac subsidia 6-axis ostentationem real-time coordinatas.

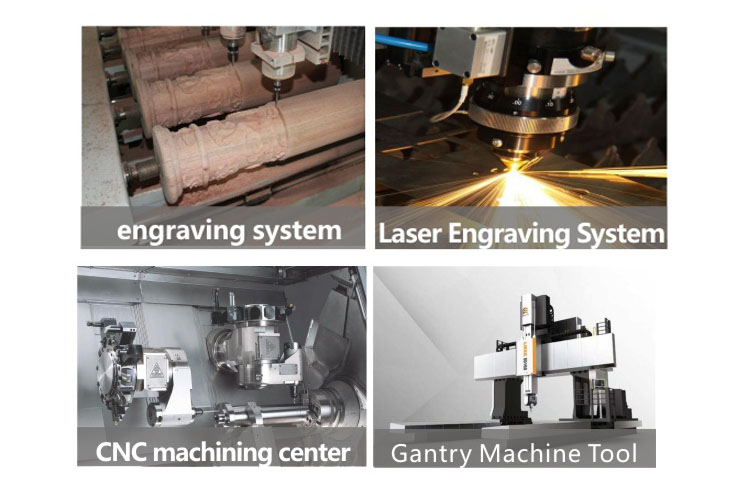

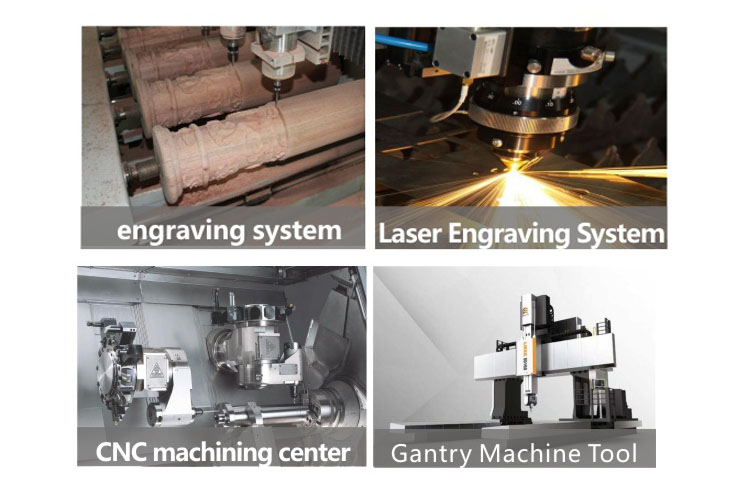

2.Applicationem agri

CNC programmabile imperium remotum late in variis CNC campis, ut laser insculptis, late adhibetur, CNC Milling Machina, CNC Machining Center, gantry instrumentum machina, etc..

3. Introductio ad principium operativum

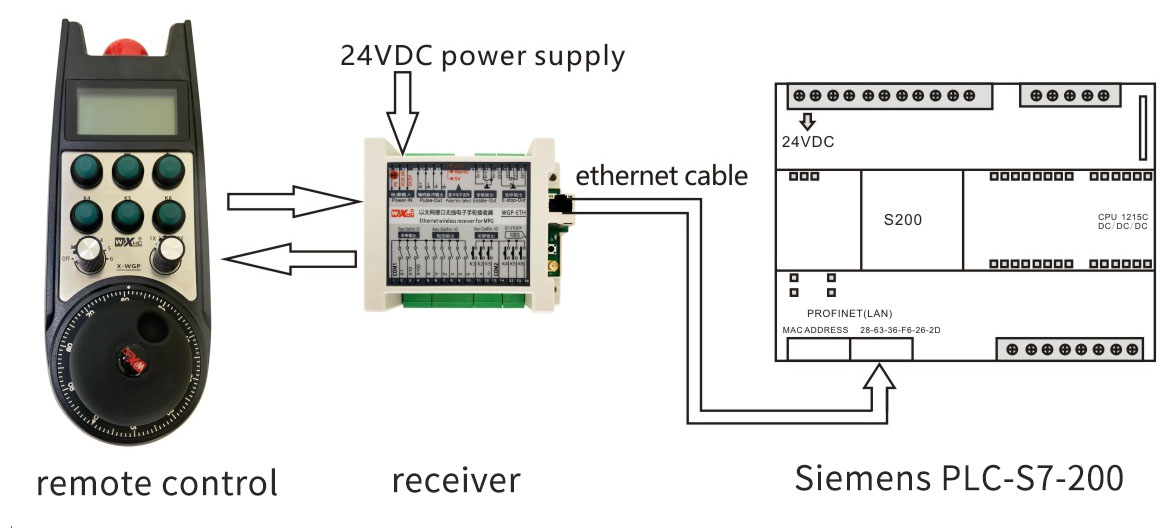

1)Electronic handwheel iungitur PLC per receptaculum Aer

a.The handwheel tradit key notitia wirelessly ad recipientis, et accipiens claves scribit per funem retis PLC system DB area; accipientis legit notitia proponendum ex designato DB area, et refert notitia ad handwheel ostentationem velum. Usor potest domicilii basim inscriptionem legendi et scribendi DB in area in handwheel, ita ut manus rotae legere et scribere notitias in DB area PLC.

b. Siemens S7 protocollo receptor sustinet. Ad PLC S7-200, PLC S7-300 et PLC S7-1200.

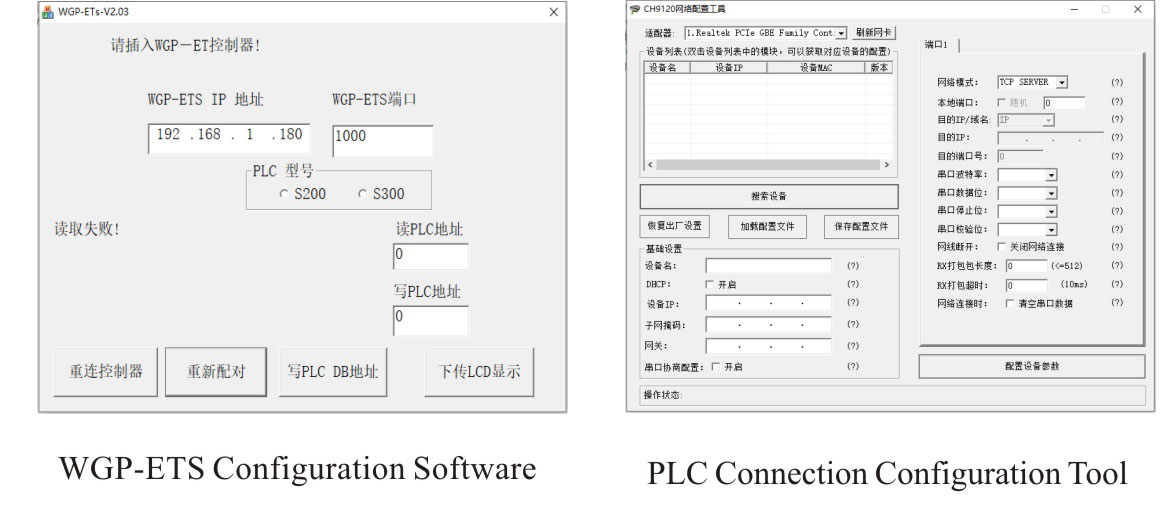

c*. Usor configurare potest recipientem modum servientis et clientis modum per PLC connexionis instrumentum configurare.

In servo modus, usor configurat PLC inscriptionem legere et scribere per WGP-ETS configurationem programmatis;Utere PLC connexionis configuratione instrumentum configurare accipientem in modum clientis. Post configuratione, receptor XWGP-ETS communicare potest cum PLC per vexillum S7 protocollo.

2)Imprimis application

Imprimis applicatio manus rotae recipientis et Siemens PLC S7-200:

a. Bulla in handwheel respondet quantitati BOOL area ab usore in PLC. Si puga handwheel pressed, in area correspondentes BOOL verum, ac dimittitur, falsum est, et basis inscriptionis BOOL area per handwheel erigi potest;

b. Handwheel valorem DB area in PLC legere potest. Una axis est 4 ostentationis data bytes, et 6 secures habent summa 24 bytes. Inscriptio basis DB areae per WGP-ETS figurationem programmatis exponi potest.

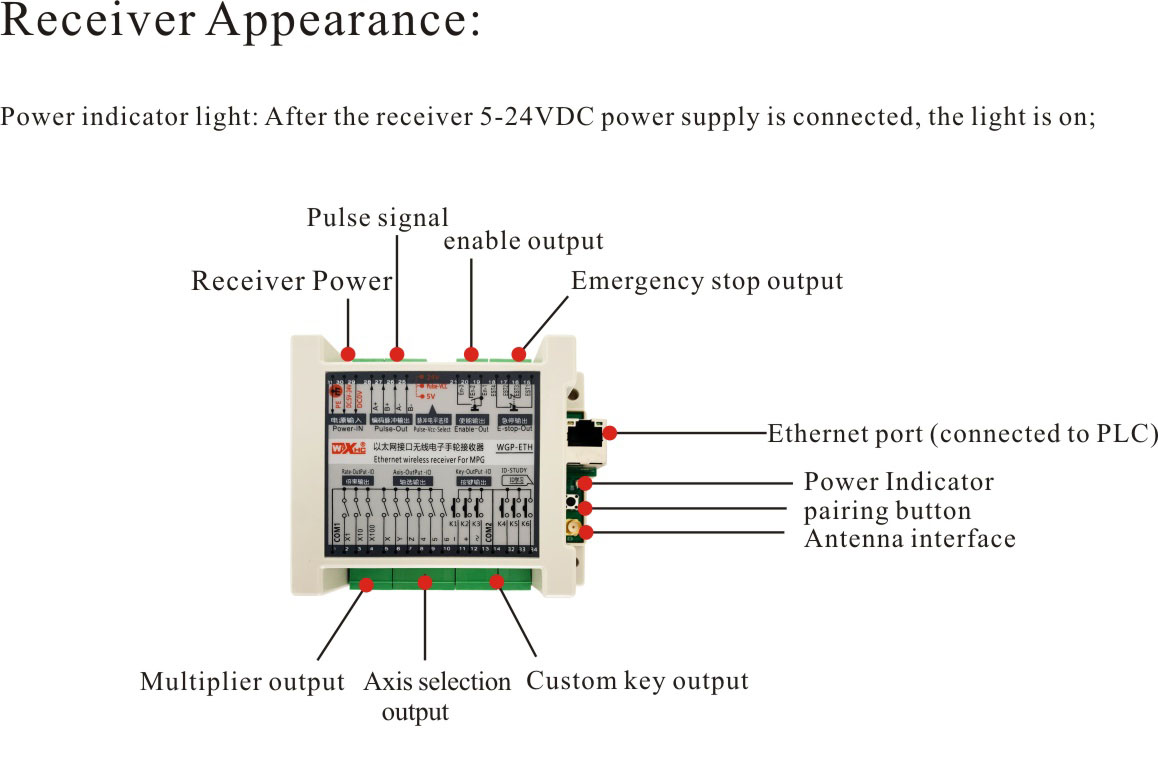

4.Aspectus introductio

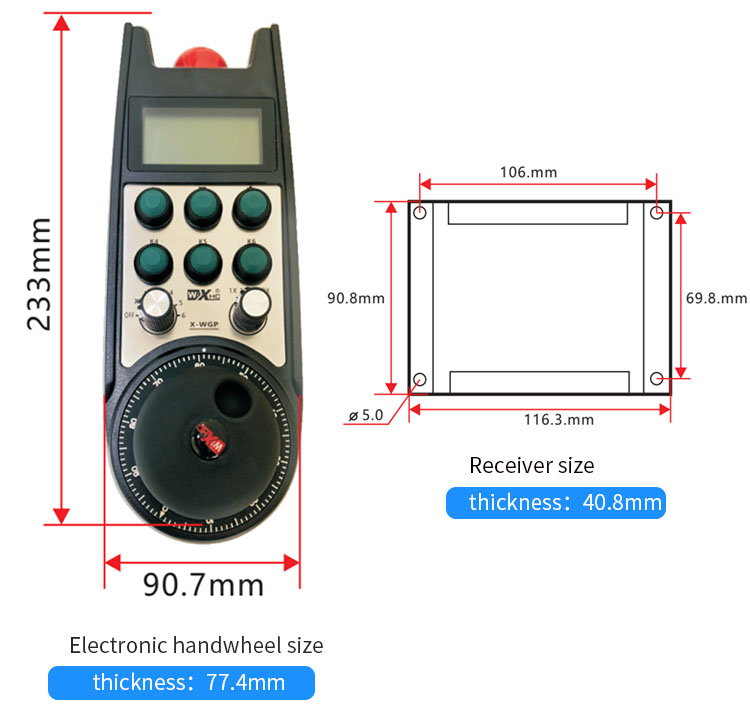

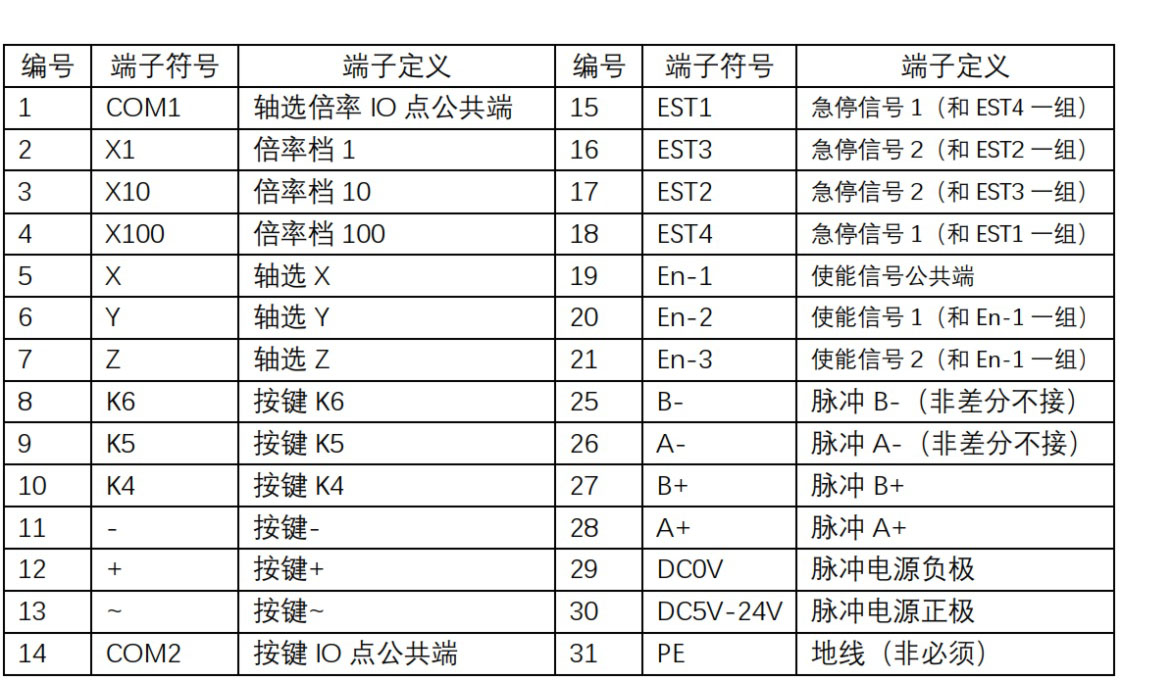

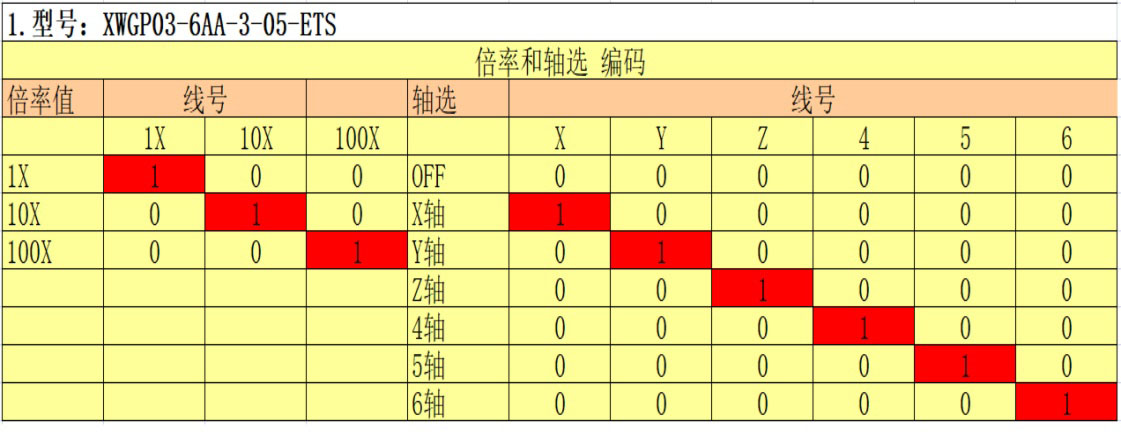

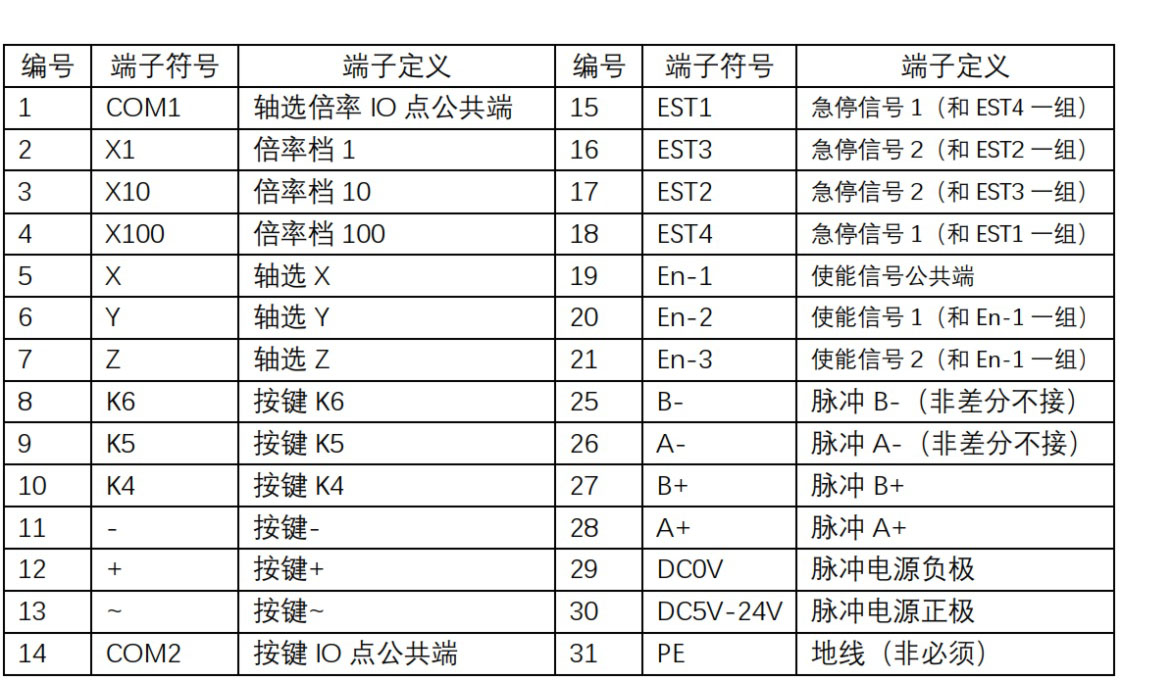

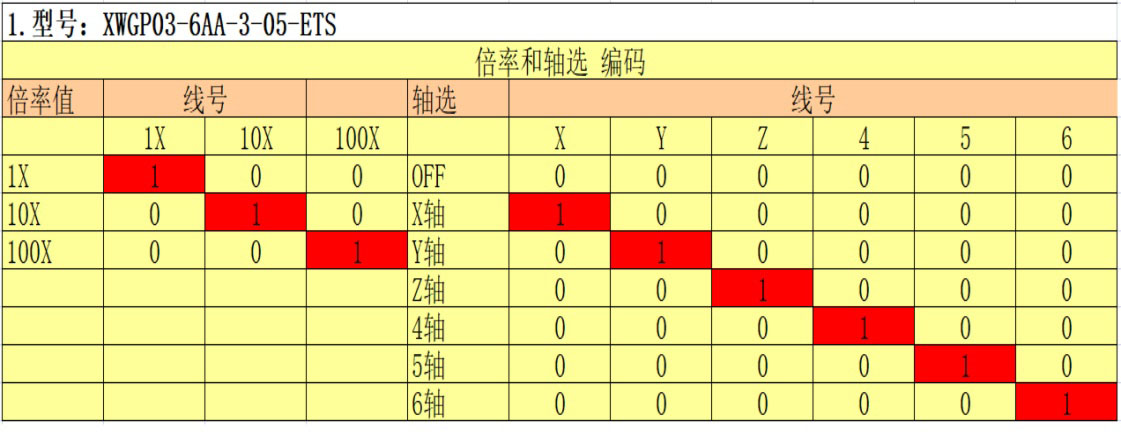

5.Receptoris terminatio definitionis et mensae coding

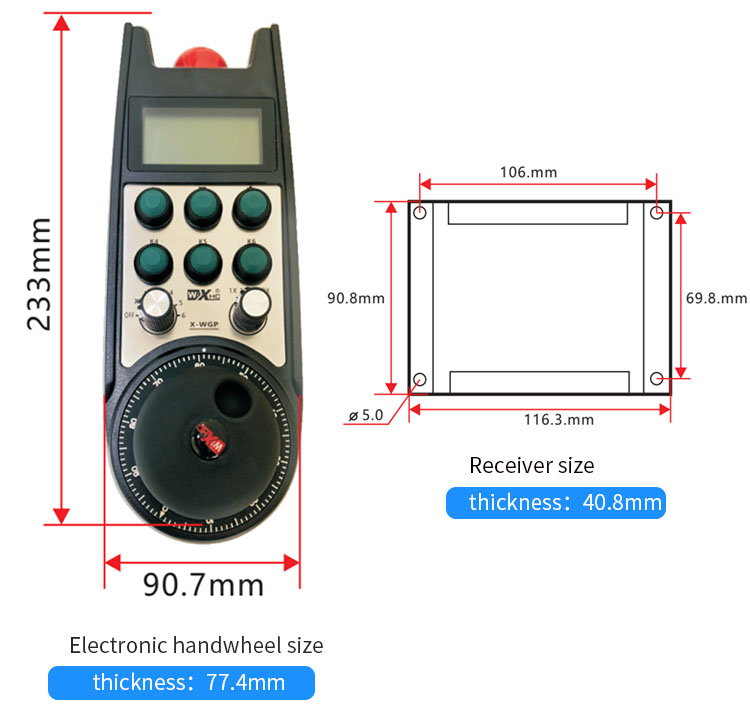

6.Aspectus magnitudine