-

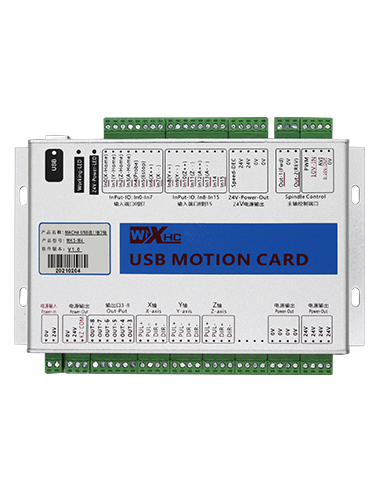

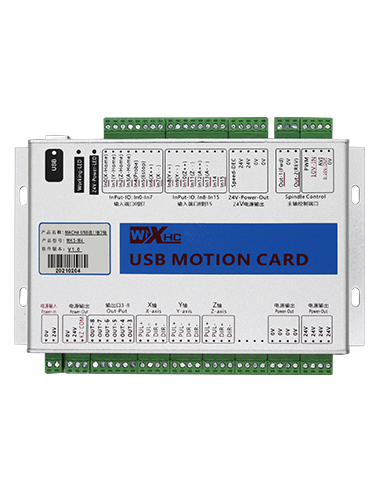

Software nt'ot'e: MACH4 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada. Características: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, Ar tarheta monitorea constantemente jar dätä hnini conexión USB. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. LED indicador ar dätä tsa̲ da mostrar conexión USB, ne jar dätä hnini operativo parpadeando. 6.16 Entrada: 8 I/Os + salida: 8 I/Os, Soporta función retroalimentación husillo, Soporta salida diferencial. Ga̲tho ya puertos I/O aislados, Interferencia-resistente, Rendimiento hingi mpa̲ti

Software nt'ot'e: MACH4 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada. Características: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, Ar tarheta monitorea constantemente jar dätä hnini conexión USB. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. LED indicador ar dätä tsa̲ da mostrar conexión USB, ne jar dätä hnini operativo parpadeando. 6.16 Entrada: 8 I/Os + salida: 8 I/Os, Soporta función retroalimentación husillo, Soporta salida diferencial. Ga̲tho ya puertos I/O aislados, Interferencia-resistente, Rendimiento hingi mpa̲ti -

Modelo: WHB04B — 4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada 1.Thuhu ar frecuencia: 433MHz,ISM,TX nts'edi 10dB,RX sensibilidad — 98dB 2.100Pulsos ya MPG redondo, Apoyo 10 Botones clave personalizados 3.Monitor LCD mostrará coordenadas mecánicas ne pieza ar 'be̲fi X/Y/Z/A/B/C, Apoyo 3 Coordenadas eje muestran xkagentho ar pa, soporte RF 64 Canales, Nu'bu̲ brecha 'ñuu 1 MHz 4. Soporte transmisión salto frecuencia, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, teclas función macro personalizada asta 10

Modelo: WHB04B — 4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada 1.Thuhu ar frecuencia: 433MHz,ISM,TX nts'edi 10dB,RX sensibilidad — 98dB 2.100Pulsos ya MPG redondo, Apoyo 10 Botones clave personalizados 3.Monitor LCD mostrará coordenadas mecánicas ne pieza ar 'be̲fi X/Y/Z/A/B/C, Apoyo 3 Coordenadas eje muestran xkagentho ar pa, soporte RF 64 Canales, Nu'bu̲ brecha 'ñuu 1 MHz 4. Soporte transmisión salto frecuencia, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, teclas función macro personalizada asta 10pantalla monitor LCD:Spindle speed value, processing feed rate value

-

Software nt'ot'e: MACH4 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada. Características: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, Ar tarheta monitorea constantemente jar dätä hnini conexión USB. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. LED indicador ar dätä tsa̲ da mostrar conexión USB, ne jar dätä hnini operativo parpadeando. 6.16 Entrada: 8 I/Os + salida: 8 I/Os, Soporta función retroalimentación husillo, Soporta salida diferencial. Ga̲tho ya puertos I/O aislados, Interferencia-resistente, Rendimiento hingi mpa̲ti

Software nt'ot'e: MACH4 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada. Características: 1.Fully supporting all Mach4 versions 2.Full support for USB hot-swappable, Ar tarheta monitorea constantemente jar dätä hnini conexión USB. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. LED indicador ar dätä tsa̲ da mostrar conexión USB, ne jar dätä hnini operativo parpadeando. 6.16 Entrada: 8 I/Os + salida: 8 I/Os, Soporta función retroalimentación husillo, Soporta salida diferencial. Ga̲tho ya puertos I/O aislados, Interferencia-resistente, Rendimiento hingi mpa̲ti -

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 32 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier 2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output7.Low power consumption design ,2pcs AA batteries can use 1 month in normal

-

Modelo: WHB04B — 4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada 1.Thuhu ar frecuencia: 433MHz,ISM,TX nts'edi 10dB,RX sensibilidad — 98dB 2.100Pulsos ya MPG redondo, Apoyo 10 Botones clave personalizados 3.Monitor LCD mostrará coordenadas mecánicas ne pieza ar 'be̲fi X/Y/Z/A/B/C, Apoyo 3 Coordenadas eje muestran xkagentho ar pa, soporte RF 64 Canales, Nu'bu̲ brecha 'ñuu 1 MHz 4. Soporte transmisión salto frecuencia, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, teclas función macro personalizada asta 10

Modelo: WHB04B — 4 4 Axis WHB04B-6 6 Axis Application software: MACH3 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada 1.Thuhu ar frecuencia: 433MHz,ISM,TX nts'edi 10dB,RX sensibilidad — 98dB 2.100Pulsos ya MPG redondo, Apoyo 10 Botones clave personalizados 3.Monitor LCD mostrará coordenadas mecánicas ne pieza ar 'be̲fi X/Y/Z/A/B/C, Apoyo 3 Coordenadas eje muestran xkagentho ar pa, soporte RF 64 Canales, Nu'bu̲ brecha 'ñuu 1 MHz 4. Soporte transmisión salto frecuencia, Stable and reliable 5.One room can run 64pcs MPG at the same time, and will not affect each other due to frequency hopping function 6.100PPR MPG function, teclas función macro personalizada asta 10pantalla monitor LCD:Spindle speed value, processing feed rate value

-

ko ya apoyo: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAN BAOYUAN,XINDAI ne bí sucesivamente. Ar manual pa mango inalámbrico totalmente funcional pa máquina grabado: Aplicaciones típicas: 'Nar variedad máquinas bo̲jä nu'u̲ CNC: made mecanizado,CNC, torno vertical, Longmen milling machine Longmen engraving and milling machine.

ko ya apoyo: SIEMENS,MITSUBISHI,FANUC,FAGOR,FRANCE NUM,TAIWAN BAOYUAN,XINDAI ne bí sucesivamente. Ar manual pa mango inalámbrico totalmente funcional pa máquina grabado: Aplicaciones típicas: 'Nar variedad máquinas bo̲jä nu'u̲ CNC: made mecanizado,CNC, torno vertical, Longmen milling machine Longmen engraving and milling machine. -

Application:ar mando mbi pa nt'ot'e Ts'ut'ubi automático sierras cuerda montadas jar pista ar mfädi pa máquinas Ts'ut'ubi t'o̲ho̲ cuerda ar klase pista

1. Support speed regulation, starting, and current reading of large motor frequency converters. 2. Support left and right track frequency converter speed regulation, starting, front, back, left and right control. 3. Support linear correction of left and right track frequency converters to keep the machine walking in a straight line. -

Application:Specially used for crawler wire saw machine

1.Supports automatic cutting mode, automatically adjusts the walking speed of the small motor according to the large motor current, and achieves automatic cutting control. 2.Barrier-free transmission distance is 200 meters. 3. Supports dual speed regulation for large motors and small motors. 4. Support small motor turning in place. 5. Supports left and right wheel small motor linear correction. -

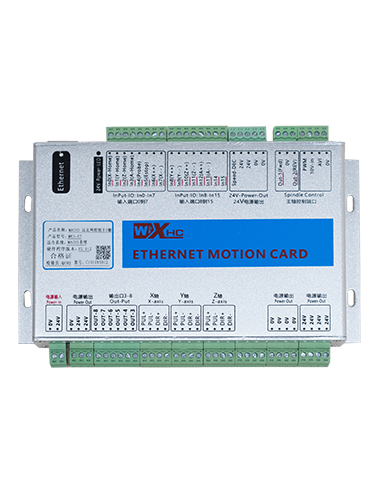

Modelo: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada. Características: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, Ar tarheta monitorea constantemente jar dätä hnini conexión USB. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. LED indicador ar dätä tsa̲ da mostrar conexión USB, ne jar dätä hnini operativo parpadeando. 6.16 Entrada: 8 I/Os + salida: 8 I/Os, Soporta función retroalimentación husillo, Soporta salida diferencial. Ga̲tho ya puertos I/O aislados, Interferencia-resistente, Rendimiento hingi mpa̲ti

Modelo: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :Máquina Ts'ut'ubi CNC. Router CNC, made mecanizado, brazo robótico, equipo producción automatizada. Características: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, Ar tarheta monitorea constantemente jar dätä hnini conexión USB. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. LED indicador ar dätä tsa̲ da mostrar conexión USB, ne jar dätä hnini operativo parpadeando. 6.16 Entrada: 8 I/Os + salida: 8 I/Os, Soporta función retroalimentación husillo, Soporta salida diferencial. Ga̲tho ya puertos I/O aislados, Interferencia-resistente, Rendimiento hingi mpa̲ti