Fakamatala

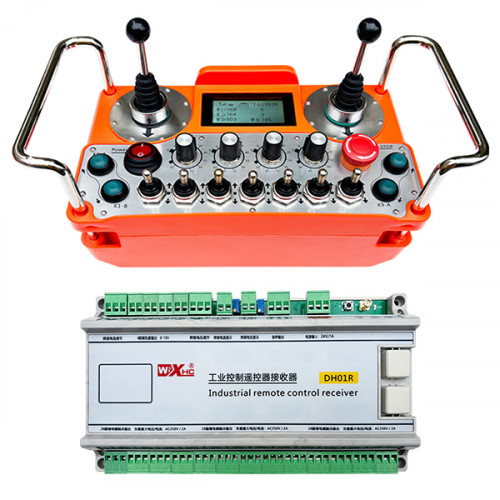

1. Koloa Fakafe'iloaki

Na'e sio 'a e maea 'o e me'alele crawler ki he pule mama'o 'otometiki 'oku fe'unga ia ki he maea 'o e crawler sio ki he ngaahi misini motuhi .. 'Oku ne 'ave 'a e 485ModbusRTU polokalama ke pule'i 'a e kamata vave mo e mu'a mo e mui 'o e pule'i 'o e fakahinohino 'o e to'ohema mo e to'omata'u 'o e inverters to'ohema mo e to'omata'u 'o e crawler ., pea pehe ki he polokalama lahi 'o e liliu 'o e tu'o lahi 'o e me'alele RTU ke pule'i 'a e kamata vave mo e 'i mu'a mo e mui 'o e pule'i 'o e fakahinohino 'o e to'ohema mo e to'omata'u 'o e crawler inverters ., pea mo e liliu lahi 'o e tu'o lahi 'o e motolo 'i he 'analaiso mo e fakafehoanaki ., fakatonutonu 'otometiki 'a e vave 'o e to'ohema mo e to'omata'u 'i he taimi mo'oni ke a'usia 'a e ngaue 'otometiki 'o e motuhi ..

2. Ngaahi fotunga koloa

1. Adopt 433MHZ 'a e tekinolosia fetu'utaki 'o e fetu'utaki ., ko e mama'o 'o e ngaue 'i he uaealesi 'oku . 100 mita.

2. Adopt 'otometiki tu'o lahi hopping ngaue, ngāue'aki 32 ngaahi seti 'o e ngaahi pule mama'o uaealesi 'i he taimi tatau ., ʻo ʻikai ke nau feʻofaʻaki ..

3. Poupou'i 'a e ngaahi inverters kotoa pe mo e 485-Modbus RTU polokalama .. Ko e ngaahi faka'ilonga inverter kuo fakafe'unga'i 'oku kau ai 'a e .:Shanghai Xielin, Fuji, Anascence, Zhongchen, Invt, ʻAkenitā. Kapau 'oku 'ikai ke ada 'a e brand kataki 'o fetu'utaki mai ki he customization ..

4. Poupou'i 'a e kamata lahi 'o e me'alele ., tu'utu'uni vave, mo e lau lolotonga.

5. Poupou ki he to'ohema mo e to'omata'u 'o e cawler vave 'o e tu'utu'uni ., kamata, pule ki mu'a mo mui he to'ohema mo e to'omata'u ..

6. Poupou'i 'a e to'ohema mo e to'omata'u 'o e crawler inverter hangatonu fakatonutonu ke tauhi 'a e misini ke nga'unu 'i ha laine hangatonu ..

7. Poupou maea sio ki he ngaue 'otometiki 'o e motuhi ., fakatonutonu 'otometiki 'a e vave 'o e to'ohema mo e to'omata'u 'i he taimi mo'oni 'o fakatatau ki he fakamatala lolotonga 'o e me'alele lahi ..

8. ʻI he taimi tatau, 'oku fe'unga ia mo e output IO fakahangatonu ke pule'i 'a e kamata mo e tu'u 'o e me'alele ., mo e analog voltage output ke pule'i 'a e vave 'o e me'alele ..

3. Ngaahi fakaikiiki 'o e koloa

4. fakafe'iloaki 'o e ngaue 'a e koloa .

Nouti:

①Screen faka'ali'ali .:

②Mode switch .:

Fakaʻaongaʻi ha switch levolo ʻe 2 ., 'oku malava ke liliu 'i he vaha'a 'o e ngaahi founga 'otometiki mo e tohi ., pea 'e fakahaa'i 'a e founga fe'unga 'i he screen ki he switching ..

③ Faka'ata:

Ngaahi pātene fakatahaʻi, 'oku fie ma'u 'e he ngaahi ngaue 'e ni'ihi ke pukepuke 'a e button faka'ata ki he ngaue ., kataki 'o vakai ki he ngaahi fakahinohino ki he switch takitaha ki he ngaahi fakaikiiki ..

④ Lahi 'a e me'alele:

Faka'aonga'i ha 3-vave reset switch ., to'o 'a e switch ko 'eni 'e lava ke ne pule'i 'a e ki mu'a mo e fakafepaki 'o e motolo lahi .. Hili hono tukuange ., 'e kei nofo pe 'a e pule'anga ., pea ʻe ʻi ai ha ngaahi fakaʻaliʻali feʻunga ʻi he screen .. 'Oku fakahaa'i 'e he t 'o e t ki mu'a ., pea 'oku fakahaa'i 'e he y ngahau 'a e rotation fakafepaki ..

⑤Si'i 'o e me'alele ki mu'a/fakafoki .:

Fakaʻaongaʻi ha switch ʻoku vave ʻene lokaʻi-kita ., 'e lava ke pule'i 'e he toho 'o e switch ko 'eni 'a e ki'i me'alele ke nga'unu ki mu'a mo mui .. 'E fakahaa'i 'e he faka'ali'ali fe'unga 'i he screen ., mo e t arrow 'oku fakahaa'i ki mu'a mo e ↓ fo'i ngahau 'oku fakahaa'i ki mui ..

⑥Remote pule'i 'a e malohi 'o e switch .:

'Oku fakamo'ui 'a e screen faka'ali'ali pule mama'o ..

⑦ si'isi'i 'a e switch 'o e liliu 'o e motu'a .:

Faka'aonga'i ha 3-vave reset switch ., ʻi he taimi ʻoku fakalele nima ai ., 'e lava ke pule'i 'a e ki'i me'alele ke afe ki he to'ohema pe to'omata'u .. ʻI hono tukuange pē, 'e ta'ofi 'e he pule mama'o 'a e ngaue ko 'eni.'I he taimi 'i he tu'unga ki mu'a ., liliu 'a e switch ko 'eni pea 'e 'asi 'a e faka'ali'ali fe'unga 'i he screen.The . + mata'itohi 'oku ne fakahaa'i 'a e tafoki to'ohema ., pea ko e – 'oku fakahaa'i 'e he ngahau 'a e liliu to'omata'u.'I he taimi 'i he founga fakafepaki ., liliu 'a e switch ko 'eni pea 'e 'asi 'a e faka'ali'ali fe'unga 'i he screen.The . + mata'itohi 'oku ne fakahaa'i 'a e tafoki to'ohema ., pea ko e – 'oku fakahaa'i 'e he ngahau 'a e liliu totonu.Peress pea puke 'a e button faka'ata ., pea liliu leva 'a e switch ko 'eni ke fakahoko ha ngaue liliu tu'u ., 'ai ke vave ange 'a e tafoki.

⑧ Lahi 'a e tu'utu'uni 'o e vave 'o e me'alele:

Faka'aonga'i 'a e tu'unga lahi 'o e encoder encoder ., vilo 'a e knob ke fakatonutonu 'a e vave S1 'o e me'alele lahi Mo e . 1 fetongitongi 'o e grid, 'oku liliu 'a e mahu'inga vave 'o e lahi 'o e me'alele 'i he fakafuofua ki he . 0.2 ngaahi ʻiuniti, pea 'e lava ke fakalelei'i vave 'e he rotation vave 'a e mahu'inga vave 'o e misini lahi ..

9 Si'isi'i 'o e vave 'o e me'alele . (fakatonutonu fakalaine):Ke faka'aonga'i 'a e knob encoder multi ., 'i he founga tohi ., he ko e meʻa kotoa pē 1 afe ʻo e foʻi tuʻuʻangá, 'oku liliu 'a e mahu'inga vave 'o e ki'i me'alele 'e he fakafuofua ki he . 0.1 ngaahi ʻiuniti. 'E lava ke fakalelei'i vave 'e he vilo vave 'a e mahu'inga vave 'o e ki'i me'alele ..

'I he founga 'otometiki ., lomiʻi ʻa e pātene fakaʻatā pea vilo . 1 grid 'i he taimi kotoa pe. 'Oku liliu 'a e mahu'inga 'o e vave 'o e vave F 'o e ki'i me'alele 'e he fakafuofua ki he . 0.1 ngaahi ʻiuniti. 'E lava ke fakalelei'i vave 'e he vilo vave 'a e mahu'inga fakangatangata 'o e vave 'o e ki'i motolo.Press 'a e button faka'ata ., liliu ʻa e tuʻunga ki he toʻomataʻú ., pea 'oku fakahaa'i 'e he faka'ali'ali fakatonutonu laine hangatonu D f .: toʻohema. Ko e fetongitongi takitaha ‘o e knob ‘oku fakalahi ia ‘aki ‘a e . 1 konga; Tafoki ki he knob hema, faka'ali'ali fakatonutonu laine hangatonu: Df: tonu. Ko e fetongitongi takitaha ‘o e knob ‘oku fakalahi ia ‘aki ‘a e . 1 konga, pea 'oku fe'unga 'a e 'iuniti fakatonutonu takitaha mo ha pule'i vave 'o e me'alele AVI 'o e feunga mo e . 0.02 V.

5. Fakatata 'o e koloa 'o e koloa

6. Fakahinohino ki hono fokotu'u 'o e koloa

6.1 Ngaahi Sitepu Koloa .

1. Fokotuʻu ʻa e meʻa tali ʻi he kapineti ʻuhilá ʻo fakafou ʻi he fuʻu ʻakau ʻi mui ., pe fokotuʻu ia ʻi he kapineti ʻuhilá ʻo fakafou ʻi he ngaahi ava ʻo e sikuluú ʻi he tuliki ʻe fā ʻo e meʻa tali ..

2. Vakai ki heʻetau fakatātā ʻo e uaea ʻoku ʻi aí ., fakafehoanaki ho'o ngaahi me'angaue 'i he feitu'u ., pea fakafehokotaki ʻa e meʻangāué ki he meʻa tali ʻo fakafou ʻi he ngaahi uaea ..

3. Hili hono fakalelei'i 'o e me'a tali ., kuo pau ke fehokotaki ʻa e ʻenitena ʻoku fakanaunauʻi ʻaki ʻa e meʻa tali ., pea ko e ngata‘anga ‘i tu‘a ‘o e ‘enitená kuo pau ke fokotu‘u pe tuku ia ‘i tu‘a ‘i he kapineti ‘uhilá .. 'Oku fokotu'u atu ke fokotu'u ia 'i he tumu'aki 'o e kapineti 'uhila ki he ola lelei taha 'o e faka'ilonga .. 'Oku tapu ke tuku 'a e 'enitena 'oku 'ikai ke fehokotaki pe fokotu'u 'a e 'enitena 'i loto 'i he kapineti 'uhila ., ‘a ia ‘e lava ke ne fakatupu ‘a e faka‘ilonga kovi mo ta‘ealafaka‘aonga‘i ..

4. Faifai pea hoko, fokotu'u 'a e maka 'i he pule'i mama'o ., fakamālohiʻi ʻa e ʻufiʻufi ʻo e pātí ., pea fakamo'ui leva 'a e ivi 'o e pule mama'o .. Hili 'a e faka'ali'ali pule mama'o 'oku fakahaa'i 'e he interface ngaue angamaheni ., 'e lava ke ke fakahoko 'a e ngaue pule mama'o ..

6.2 Ngaahi tafa'aki fokotu'u 'o e ma'u .

6.3 Fakatata 'o e Fakafepaki 'o e uaea 'o e ma'u .

7. Ngaahi fakahinohino ki he ngaue 'a e koloa .

7.1 Ngaahi tu'unga 'o e Pule'i 'o e Pule'i

Founga ke fakahu ai 'a e ngaahi fakangatangata 'o e muimui'i 'o e pule mama'o .: liliu 'a e founga 'o e mode ki he founga tohi ., fakatonutonu ‘a e vave ‘o e ki‘i me‘alelé ki he . 25, pē 0, 10, 20, 40, 50, pea liliu 'a e switch ki mu'a 'o e misini lahi ki 'olunga . 3 taimi pea holo hifo . 3 taimi;

Fakaʻaongaʻi ʻa e . “Pule'i vave 'o e Moto .” knob ke liliu e peesi ., lomi'i Faka'ata mo liliu 'a e ki'i knob pule'i vave 'o e motolo ke fakalelei'i 'a e ngaahi fakangatangata .; hili hono fakalelei'i, hiki ʻa e peesi ki he ngataʻangá ., fili Save mo e Hu ki tu'a ., pea lomiʻi ʻa e Fakaʻatā ke mavahe mei he menu .;

Ko e ngaahi fakangatangata 'oku hange ko 'eni .:Lolotonga lahi taha: lahi 'o e mahu'inga 'o e ngaahi fakakaukau lolotonga 'o e motolo ., fokotu'u 'o e 15-200A, tefito 60;

vave 'a e pule'i 'o e ngaahi fakangatangata: founga 'otometiki si'isi'i 'otometiki 'o e vave 'otometiki ., ko e si'isi'i ange ia, fokotu'utu'u 'o e fokotu'utu'u 200-1500, tefito 1000;

Parameter 'o e fakatauele'i: Seti 'a e fakangatangata 'i 'olunga 'o e liliu vave 'o e me'alele 'oku faka'ata .. Ko e taimi 'oku liliu ai 'a e lolotonga 'o fakalaka atu 'i he mahu'inga ko 'eni ., te ne fakasiʻisiʻi. Ko e si'isi'i ange ia ., ko e vave ange 'a e holo hifo 'a e ngaahi misini to'ohema mo e to'omata'u .. Ko e 'atakai 'oku 05-12, pea ko e default ko e . 06;

Fakavavevave a1.: Ko e lahi ange 'a e mahu'inga ., ko e vave ange 'a e vave 'o e vave 'o e me'alele ., 'o e 00-06,default 01; Fakatapui a2.: Ko e lahi ange 'a e mahu'inga ., ko e vave ange 'a e holo hifo 'a e vave 'o e me'alele ., kehekehe 00-06, tefito 02;

Faka'ata 'a e tu'utu'uni vave .: Pe 'oku fie ma'u ke faka'ata 'a e ki'i tu'utu'uni vave 'o e motolo ., 00 'oku 'ikai ke faka'ata, 01 'oku faka'ata, tefito 01;

Kamata ʻi he lokaʻi-kitá: Pe 'e 'otometiki pe 'a e motolo lahi 'o kei 'i ai pe 'a e self-locking hili 'a e switch 'i mu'a mo e reverse 'oku tukuange ., 00 'oku 'ikai ke tauhi, 01 'oku tauhi, tefito 01;

fononga lahi taha: Ko e vave lahi taha 'o e ngaahi misini to'ohema mo e to'omata'u ., kehekehe 10-100, tefito 50;

Ko hono motuhi ʻo e lolotongá: Ko e motuhi lahi taha ., 'oku fakahaa'i 'e he screen 'a e mahu'inga IC ., kehekehe 15-160, tefito 30, 'oku fakahaa'i 'e he screen 'a e IC .: 30. Ko e fakangatangata 'i 'olunga 'o e parameter ko 'eni = lahi taha x . 80%;

Fakangatangata vave 'o e default .: Ko e vave 'o e motuhi 'otometiki 'o e motolo 'i he kamata'anga ., kehekehe 00-100, tefito 10, 'oku fakahaa'i 'e he screen 'a e F1.0., 'oku tonu pe 'a e parameter ko 'eni 'i he taimi 'oku fokotu'u ai 'a e fononga lahi taha ke . 50.

halanga uaealesi: Ko e default 'oku 10. 'I he taimi 'oku 'ikai tu'uma'u ai 'a e faka'ilonga pule mama'o pe 'oku 'i ai ha fakalavea 'o e faka'ilonga 'i he feitu'u ., 'e lava ke ke fakalelei'i 'a e parameter ko 'eni ke liliu 'a e ngaahi halanga ke faka'ehi'ehi mei he fakalavea .;

offset vave .: Ko e fakangatangata 'i 'olunga 'o e vave 'o e motuhi 'otometiki 'o e ki'i me'alele .,kehekehe 00-200, tefito 60, ngaahi faka'ali'ali 'o e screen . 6.0; Faka'ali'ali 'a e fakangatangata 'o e mahu'inga 'i 'olunga = fakangatangata 'o e vave 'o e offset × . 0.1;

Host lahi taha: Ko e vave taha 'o e misini lahi ., kehekehe 10-100, tefito 50;

Me'angaue Mbus ( tu'utu'uni pau ): Fili lahi 'o e sipinga 'o e inverter 'o e me'alele ., kehekehe 00-03, tefito 03;

00- Shanghai Xielin 01 Fuji

02- Invt 03 Fo'ou–Zhongchen, Lōkoni–Ko e

SBUS me'angaue (tu'utu'uni pau): Si'isi'i 'o e tu'o lahi 'o e me'alele converter 'a e sipinga 'o e sipinga ., kehekehe 00-05, tefito 03;

00- Shanghai Xielin 01 Fuji

02- Invt 03 Fo'ou–Zhongchen, Lōkoni–Ko e

04-Anchuanda 05-'Ikai ha taha

8. Koloa 'o e koloa

7.2 Ko e fokotu'utu'u 'o e parameter 'o e converter tu'o lahi .

1. Fili 'o e ma'u'anga fakamatala 'o e fekau: Ko e founga fekauʻaki ʻo e fetuʻutakí

2. Fili 'o e tu'o lahi 'o e fili .: fetu'utaki 'oku fai

3. Tu'unga ma'u: 19200

4. Founga 'o e fotunga: No fakamo'oni'i, founga fakamatala<8-N-10.>

5. tu'asila fakalotofonua: Seti 'a e converter tu'o lahi to'ohema ki he . 1, ko e liliu tu'o lahi totonu ki he . 2, pea mo e liliu lahi 'o e tu'o lahi 'o e me'alele ki he . 3

7.3 Ngaahi Fakahinohino ki he Ngaue Mamafa

1. Mafai 'i he misini ., fakamo'ui 'a e pule mama'o ., hū ki he puipuituʻa ʻo e puleʻi mamaʻó ., fokotu'u 'a e ngaahi fakangatangata 'o e pule'i 'o e mama'o ., tefito 'i he fokotu'u 'a e ngaahi sipinga 'o e fanga ki'i mo e lahi 'o e tu'o lahi 'o e me'alele . (skip 'a e sitepu ko 'eni kapau kuo 'osi fokotu'u kinautolu 'e he kautaha ngaohi misini .);

2. Seti 'a e ngaahi fakangatangata 'o e converter tu'o lahi . (skip 'a e sitepu ko 'eni kapau kuo 'osi fokotu'u ia 'e he kautaha ngaohi misini .);

3. Seti 'a e pule mama'o ki he founga tohi ., pea ngāue‘aki leva ‘a e pule mama‘ó ke hiki ‘a e mīsiní ki he tu‘unga ngāué .;

4. 'I he founga tohi ., fokotu'u 'a e mahu'inga 'o e IC ki he lolotonga 'o e motuhi 'o e misini lahi mo e vave 'o e misini lahi .;

5. Fetongi ki he founga 'otometiki pea fokotu'u 'a e fakangatangata vave 'o e motuhi F ki he ki'i me'alele .;

6. 'I he founga 'otometiki ., afe 'a e fu'u me'alele lahi 'o e me'alele ki mu'a ke kamata 'a e misini lahi ., pea liliu leva 'a e ki'i me'alele ki mu'a pe fakafoki .. 'Oku hū 'a e pule mama'o ki he founga 'o e motuhi 'otometiki pea kamata ke motuhi ..

9.Tauhi

1. Kataki 'o ngaue'aki ia 'i ha 'atakai momoko 'i he mafana 'o e loki mo e 'omi ke fakaloloa 'ene mo'ui 'i he ngaue ..

2. Kataki 'o faka'ehi'ehi mei hono ngaue'aki 'i he ngaahi 'atakai 'oku 'ikai angamaheni hange ko e 'uha mo e ngaahi pupula vai ke fakaloloa 'a e mo'ui 'o e ngaue ..

3. Kataki 'o tauhi 'a e loki 'o e maka mo e 'elia 'o e shrapl ukamea ke ma'a ..

4. Kataki 'o faka'ehi'ehi mei he maumau'i 'o e pule mama'o koe'uhi ko e squeezing mo e hinga ..

5. Kapau 'oku 'ikai ke ngaue'aki 'i ha taimi loloa ., kataki 'o to'o 'a e maka pea tauhi 'a e pule mama'o mo e 'uhila 'i ha feitu'u ma'a mo malu ..

6.Lolotonga hono tauhi mo fefononga'aki ., 'oku totonu ke tokanga ki he moisture mo e 'ohovale 'a e fakafepaki ..

10. Fakamatala ki he Malu

1. Kataki 'o lau fakalelei 'a e ngaahi fakahinohino kimu'a pea toki ngaue'aki pea tapui 'a e kau mataotao 'oku nau ngaue ..

2. Kataki 'o fetongi 'a e maka 'i ha founga taimi totonu 'i he taimi 'oku fu'u ma'ulalo ai 'a e maka ke faka'ehi'ehi mei he ngaahi fehalaaki 'oku fakatupu 'e he malohi 'oku 'ikai fe'unga ., 'a ia 'e lava ke iku ki he pule mama'o 'oku 'ikai lava ke fakalele ..

3. Kapau 'oku fiema'u ke fakalelei'i ., Kataki 'o fetu'utaki ki he kautaha ngaohi .. Kapau 'oku tupu 'a e maumau 'i he fakalelei'i 'o e ., 'e 'ikai ke 'oatu 'e he kautaha ngaohi 'a e warranty .