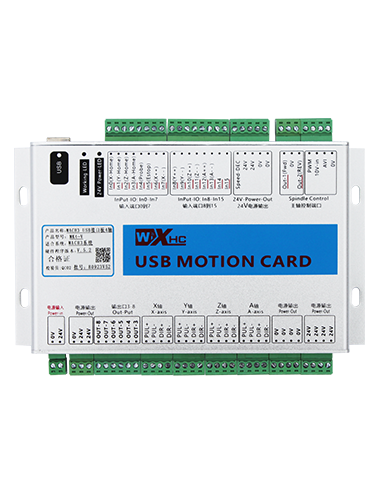

- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

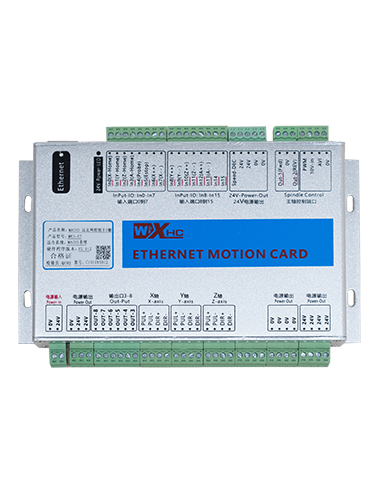

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

Model: MK3-ET 3AXIS MK4-ET 4AXIS MK6-ET 6AXIS Application software: MACH3 Application Control card application industry :CNC cutting machine. CNC router.Machining Center.Mechanical arm.Automated production equipment. Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance -

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,stable performance

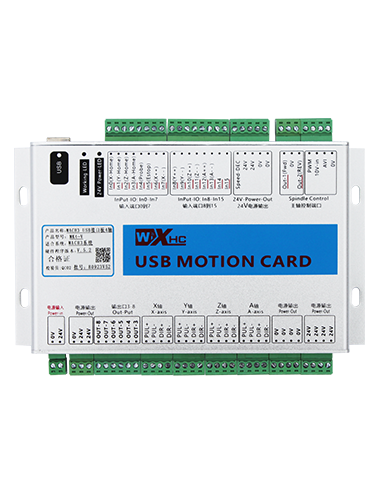

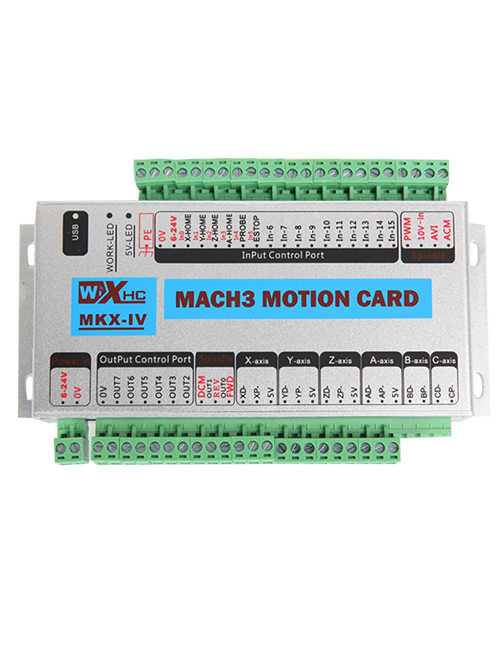

- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,stable performance

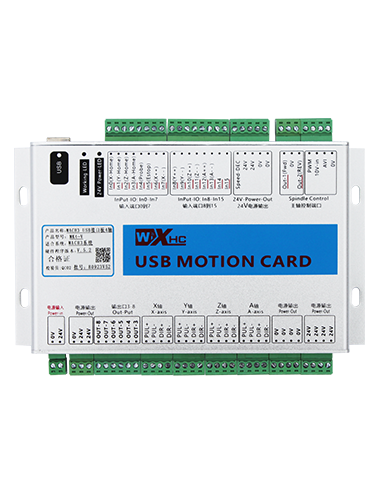

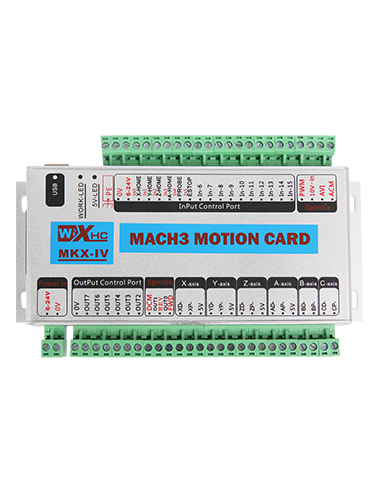

- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,

Features: 1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 6-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing. 6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference,stable performance

- MACH3 system

- Supports MAX 6-axis

- Maximum step-pulse frequency is 2000KHz

-

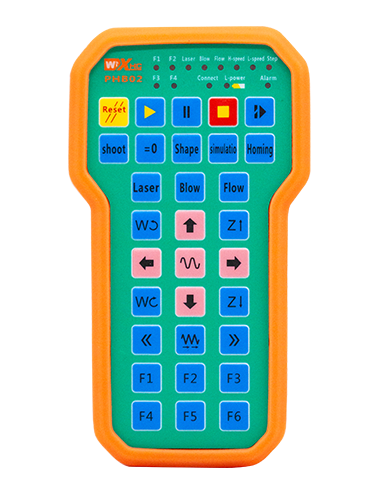

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 32 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

- Provide DLL library file for Windows

- Provide VC example programs for electronic handwheel applications, including VC source code

- Secondary development

-

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 31 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

- Provide DLL library file for Windows

- Provide VC example programs for electronic handwheel applications, including VC source code

- Secondary development

-

1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 4-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing.

1.Fully supporting all Mach3 versions 2.Full support for USB hot-swappable, the card is Monitoring USB connection status at any time. 3.Supports MAX 4-axis 4.Maximum step-pulse frequency is 2000KHz 5. Status indicator LED can be useful to show the USB connection, and working stauts by flashing.6.16 input IO+8output IO, support spindle feedbackfunction, support difference output. all IO-port isolation, interference, stable performance

- MACH3 system

- Supports MAX 4-axis

- Maximum step-pulse frequency is 2000KHz

-

1. Provide DLL library file for Windows 2. Provide VC example programs for electronic handwheel applications, including VC source code 3.USB interface, adopt USB1.1 full speed transmission 4. Customer secondary development 5. Provide 128 * 64 dot matrix LCD display, customers can download the display content through DLL 6. Provides 31 key inputs 7. Provide 100PPR electronic handwheel input 8. Barrier-free operating distance: 40 m 9. Patented XHC wireless transmission protocol; automatic frequency hopping, strong anti-interference ability 10. Low power consumption design: 2 AA batteries, use time 30 days 11.32 sets of equipment, simultaneous use does not affect 12. Industrial-grade design, dust-proof design, stable and reliable.

- Provide DLL library file for Windows

- Provide VC example programs for electronic handwheel applications, including VC source code

- Secondary development

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier 2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output7.Low power consumption design ,2pcs AA batteries can use 1 month in normal

- 200M barrier free transmission

- Support 4lines 250v/3A relay output

- Easy to use

-

Application:Welding machine automation welding and welding operator.Turn Rolls

1.Use 433MHZ wireless transmission frequency .long distance wireless frequency hopping technology .wireless control distance 200m without barrier 2.In the same working area,it can support 32pcs equipments used at the same time 3.LCD monitor can display present welding current ,voltage and speed 4.Support 4lines 250v/3A relay output.to control contactor achieve motor clock wise/counter-clock wise 5.Support 1lines 0-10v analog voltage output to control VFD speed adjustment 6.1 line normal open E-stop signal output7.Low power consumption design ,2pcs AA batteries can use 1 month in normal

- 200M barrier free transmission

- Support 4lines 250v/3A relay output

- Easy to use

-

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output8.Low power design, only 3 AA batteries for a month

- 200M barrier free transmission

- 25 way 250V/3A relay output, control contactor

- Easy to use

-

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output

25 switch quantities, 4 analog quantities, buttons can be used for subtraction, panels can be customized, used in electric welding machines, roller frames, wire saw cutting and other industries Using 433 communication protocol and remote wireless frequency hopping transmission, the wireless remote control of electric welding machine is realized. Application:electric welding turning rolls 1.433 wireless transmission protocol, long distance wireless frequency hopping, 200M barrier free transmission 2.Support 32 sets of equipment at the same place at the same time 3.Display welding current, welding voltage and welding speed 4. Two roads of 5K isolation digital potentiometer output, realize welding current and voltage remote control 5. Two 10V analog voltage output, control converter speed regulation. 6.25 way 250V/3A relay output, control contactor 7.Emergency stop relay output8.Low power design, only 3 AA batteries for a month

- 200M barrier free transmission

- 25 way 250V/3A relay output, control contactor

- Easy to use