應用:自動切割軌道繩索鋸的遙控器適用於軌道類型繩索切割機

1. 支持速度法規, 開始, 和當前大型電動機轉換器的讀數.

2. 支持左右軌道頻率轉換器速度法規, 開始, 正面, 後退, 左右控制.

3. 支持左右履帶變頻器線性校正,保持機器行走平穩

直線.

應用:自動切割軌道繩索鋸的遙控器適用於軌道類型繩索切割機

1. 支持速度法規, 開始, 和當前大型電動機轉換器的讀數.

2. 支持左右軌道頻率轉換器速度法規, 開始, 正面, 後退, 左右控制.

3. 支持左右履帶變頻器線性校正,保持機器行走平穩

直線.

履帶車繩鋸自動切割遙控器適用於履帶式繩鋸

切割機. 它使用 485 Modbus RTU協議控制左右聲道頻率

轉換器, 以及大型電機變頻調速啟動和前置, 後部,

左右方向控制器. 並且可以讀取大頻率電機的工作電流

轉換器通過 485 Modbus RTU協議. 通過分析比較當前

大電機, 左右軌道速度可實時自動調節

實現自動切割功能.

1. 採用433MHz無線通訊技術, 無線操作距離為 100 儀表.

2. 採用自動跳頻功能並使用 32 無線遙控器套

同時地, 互不影響.

3. 支持所有變頻器 485 Modbus RTU協議, 和當前兼容的頻率

轉換器品牌包括:Shanghai Xielin, 富士, Huichuan, Zhongchen, 英威騰, 和 . 對於品牌

不兼容的, 請聯繫我們定制.

4. 支持速度法規, 開始, 和當前大型電動機轉換器的讀數.

5. 支持左右軌道頻率轉換器速度法規, 開始, 正面, 後退, 左右控制.

6. 支持左右履帶變頻器線性校正,保持機器行走平穩

直線.

7. 支持繩鋸自動切割功能, 自動調節左右軌道速度

實時根據大電機當前信息.

8. 還兼容直接IO輸出控制電機啟停, 和模擬電壓輸出

電機速度控制.

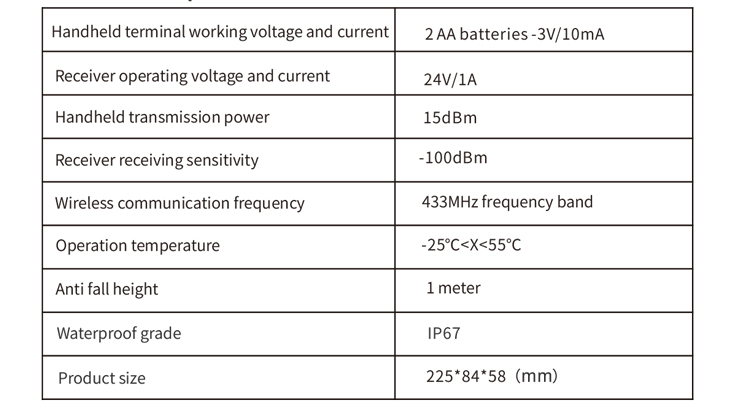

3. 產品規格

4. 產品功能介紹

筆記:

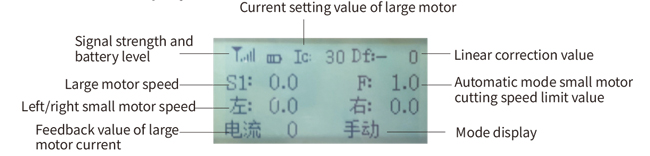

①屏幕顯示:

②模式切換:

③啟用:

組合按鈕, 部分操作需要按住啟用按鈕才能進行操作,詳細信息請參閱每個開關的說明.

④大電機開關:

使用 3 速復位開關, 拉動此開關可控制大電機正反轉. 發布後, 國家將繼續存在, 並且屏幕上會有相應的顯示. S1↑箭頭表示正轉, S1↓箭頭表示反向旋轉.

⑤小電機正反轉開關:

小電機前面裝有3檔自鎖開關. 按下啟用按鈕並拉動此開關可以控制小電機前進和後退, 屏幕上會出現相應的顯示。 ↑↑箭頭代表前進, ↓↓箭頭代表向後.

⑥ 直線校正:

使用多圈編碼器旋鈕, 按啟用按鈕, 向右轉動旋鈕, 並顯示直線校正: df: 左旋鈕增加 1 每轉單位, 和左邊

電機速度增加 0.1 單元; 向左轉動旋鈕, 直線校正顯示: df: 在右側, 旋鈕每轉一圈都會增加 1 單元, 右側電機的速度增加

經過 0.1 單元.

⑦小電機轉動開關:

使用 3 速復位開關, 手動操作時, 可控制小電機左轉或右轉. 一旦發布, 遙控器會自動停止此動作. 前進狀態下, 當這個開關打開時, 屏幕上會出現相應的顯示. ←↑箭頭表示左轉, ↑→箭頭表示右轉。倒車模式時, 轉動此開關,屏幕上會出現相應的顯示. ←↓箭頭表示左轉, ↓→箭頭表示右轉.

⑧ 大電機調速:

使用多圈編碼器旋鈕, 旋轉 1 每次都格子, 大電機的速度值變化約 0.2 單位. 快速旋轉可以快速修改大電機的速度值.

⑨ 小電機調速:

使用多圈編碼器旋鈕, 在手動模式下, 按下啟用按鈕,然後一次旋轉一個網格,左右小電機的速度值變化約 0.1 單位, 快速旋轉可以快速修改小電機的速度值。在自動模式下, 按下啟用按鈕並一次旋轉一個網格,小電機的速度限制值F變化約 0.1 單位. 快速旋轉可快速修改小電機的速度限制值.

⑩ 遙控電源開關

遙控器顯示屏亮起.

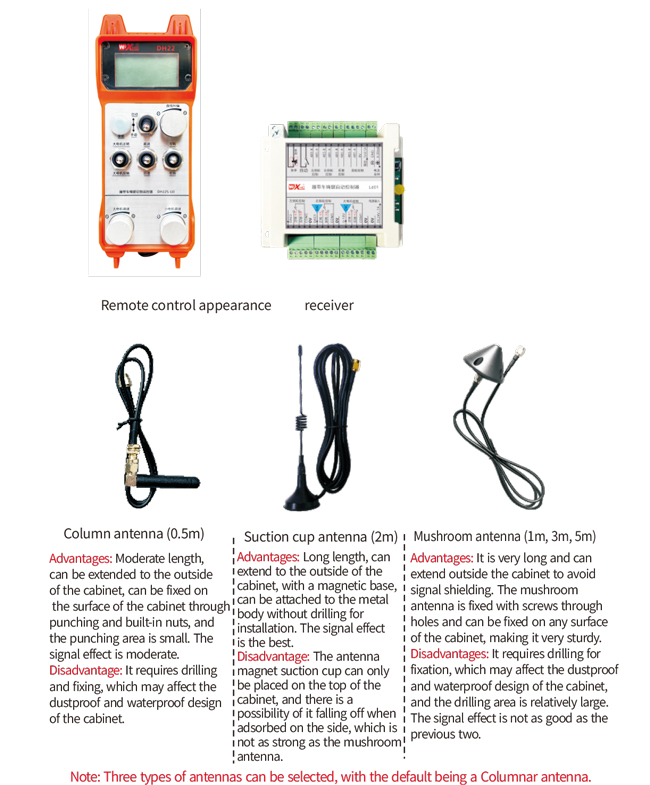

5. 產品配件圖

6. 產品安裝指南

6.1 產品安裝步驟

1. 通過背面卡扣將接收器安裝到電氣櫃內, 或通過接收器四個角的螺孔安裝到機櫃中.

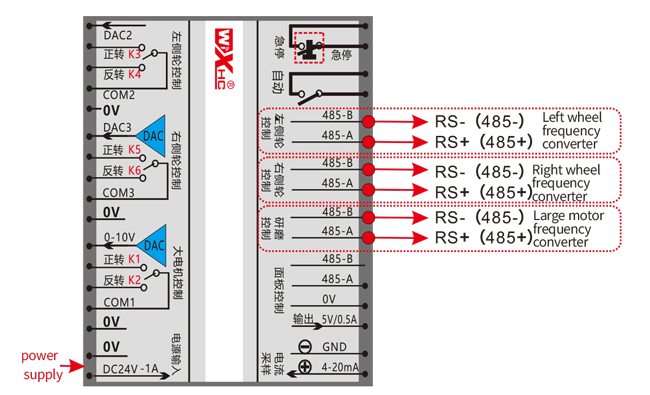

2. 請參閱我們的接收器接線圖並將其與您的現場設備進行比較. 通過電線將設備與接收器連接.

3. 固定好接收器後, 需連接接收器配備的天線,並將天線外端安裝或放置在電氣櫃外. 建議放置於電氣櫃頂部,信號效果最佳. 禁止將天線不連接或放置在電氣櫃內, 因為這可能會導致信號無法使用.

4. 最後, 將電池安裝到遙控器上, 擰緊電池蓋, 並打開遙控器電源開關. 遙控器顯示屏顯示正常後

工作界面, 可進行遠程控制操作.

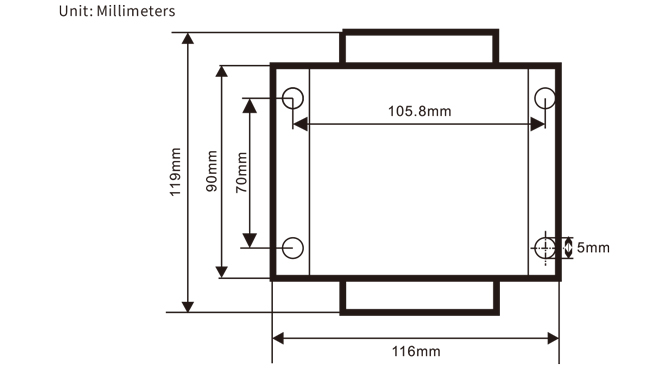

6.2 接收器安裝尺寸

6.3 接收器接線參考圖

7. 產品操作說明

7.1 遠程控制參數設置

遠程控制後台參數輸入方法:

將模式開關轉到手動模式, 調節小電機的速度 25 兩側, 或者 0, 10, 20, 40, 50 在所有方面, 並連續將大電機的前進開關撥到上方 3 次數和次數 3 次;

使用 “小電機調速” 旋鈕翻頁, 按啟用按鈕, 然後轉動小電機調速旋鈕修改參數. 修改後, 將這一頁翻到最後,選擇 “節省” 退出, 然後按啟用按鈕退出菜單;

參數如下:

最大電流: 大電機電流反饋範圍, 設定範圍15-200A, 預設 100;

速度控制參數: 自動模式, 小電機自動加速或減慢,越小越快, 設定範圍 200-1500, 預設 800;

加減速參數: 設置允許電機轉速變化的上限. 當電流變化超過該值時, 將會發生減速. 越小, 左右電機減速越快, 與一系列 05-12 和默認值 06;

加速度a1: 電機轉速越大, 增加得越快, 與一系列 00-06 和默認值 01;

減速度a2: 電機轉速越大, 減少得越快, 與一系列 00-06 和默認值 02;

啟用速度調節: 小電機調速是否需要開啟? 00 不啟用, 01 使, 默認是 01;

開始自鎖: 鬆開正反轉開關後大電機是否自動保持自鎖? 00 不成立, 01 持有, 預設 01

最大步行距離: 左右電機最高轉速, 範圍 10-100, 預設 50;

切割電流: 最大切割電流, 屏幕上顯示IC值, 範圍 15-160, 預設 30,

對應IC: 30 顯示在屏幕上. 該參數的上限為 80% 最大電流;

默認速度限制: 開機時默認小電機自動切割速度在以下範圍內 0-100, 默認為 10. 屏幕顯示F1.0, 並且該參數僅在最大步行設置為時才准確 50.

自動模式: 設置為 00, 自動/手動開關是模式開關. 設置為 01, 自動/手動開關設置到自動位置, 顯示屏顯示燈光, 並且接收器上的自動終端輸出關閉. 當設置為手動時, 自動輸出端子斷開;

限速偏差: 小電機自動切割速度上限範圍為 00 到 200, 默認為 60 以及相應的顯示 6.0 在屏幕上; 顯示值上限=速度限制偏置x 0.1;

最大主機數: 大電機最高轉速, 範圍 10-100, 預設 50;

M總線設備 (強制的): 大電機變頻器型號的選擇, 範圍 00-03, 預設 03;

00- Shanghai Xielin 01-Fuji

02-英威騰03-匯川技術(中辰), 羅賓康)

SBUS設備 (強制的): 小電機變頻器選型, 範圍 00-05, 預設 03;

00- Shanghai Xielin 01-Fuji

02-英威騰03-匯川技術(中辰), 羅賓康)

04-安川達05-無

7.2 變頻器參數設置

1. 命令源選擇: 通訊命令通道

2. 主頻率源選擇: 給予溝通

3. 波特率: 19200

4. 數據格式: 沒有驗證, 數據格式<8-N-1>

5. 本地地址: 將左側變頻器設置為 1, 正確的變頻器 2, 和

大型電機變頻器 3

7.3 遙控器操作說明

1. 打開機器電源, 打開遙控器, 進入遠程控制後台, 設定

遠程控制後台參數, 主要設置小電機和大電機頻率

轉換器型號: (如果機器製造商已設置,則跳過此步驟);

2. 設置變頻器參數 (如果機器製造商

已經設置了);

3. 將遙控器設置為手動模式, 然後使用遙控器將機器移動到

工作位置;

4. 手動模式下, 設置大電機的切割電流IC和大電機的轉速

5. 切換到自動模式並設置小電機切割速度限制F值;

6. 自動模式下, 將大電機開關撥至正轉,啟動大電機, 然後轉動

小電機切換前進或後退, 遙控器進入自動切割

開始切割模式.

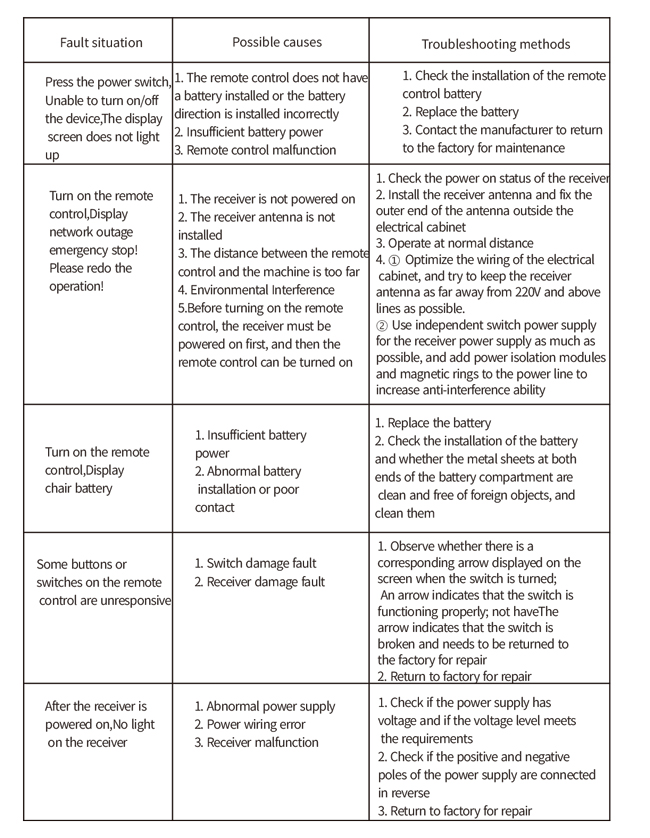

8.產品故障排除

9.維護

1. 請在室溫和壓力下在乾燥的環境中使用它以延長其使用壽命.

2. 請避免在雨水和水泡等異常環境中使用以延長使用壽命.

3. 請保持電池倉及金屬彈片區域清潔.

4. 請避免擠壓、跌落損壞遙控器.

5. 如果很長一段時間沒有使用, 請取出電池並將遙控器和電池存放在乾淨的地方

和安全的地方.

6.在存儲和運輸過程中, 應注意水分和電擊性.

10. 安全信息

1. 請在使用前仔細閱讀說明,並禁止非專業人員操作.

2. 電池電量過低時請及時更換電池,以免造成錯誤

電量不足, 可能會導致遙控器無法操作.

3. 如果需要維修, 請聯繫製造商. 如果損害是由自修理造成的, 製造商

將不提供保修.