应用:自动切割轨道绳索锯的遥控器适用于轨道类型绳索切割机

1. 支持速度法规, 开始, 和当前大型电动机转换器的读数.

2. 支持左右轨道频率转换器速度法规, 开始, 正面, 后退, 左右控制.

3. 支持左右轨道频率转换器的线性校正,以使机器行走

直线.

应用:自动切割轨道绳索锯的遥控器适用于轨道类型绳索切割机

1. 支持速度法规, 开始, 和当前大型电动机转换器的读数.

2. 支持左右轨道频率转换器速度法规, 开始, 正面, 后退, 左右控制.

3. 支持左右轨道频率转换器的线性校正,以使机器行走

直线.

履带车绳锯自动切割遥控器适用于履带式绳锯

切割机. 它使用 485 Modbus RTU协议控制左右声道频率

转换器, 以及大型电机变频调速启动和前置, 后部,

左右方向控制器. 并且可以读取大频率电机的工作电流

转换器通过 485 Modbus RTU协议. 通过分析比较当前

大电机, 左右轨道速度可实时自动调节

实现自动切割功能.

1. 采用433MHz无线通讯技术, 无线操作距离为 100 仪表.

2. 采用自动跳跃功能并使用 32 无线遥控器套

同时地, 不互相影响.

3. 支持所有变频器 485 Modbus RTU协议, 和当前兼容的频率

转换器品牌包括:Shanghai Xielin, 富士, Huichuan, Zhongchen, Invt, 和 . 对于品牌

不兼容的, 请联系我们定制.

4. 支持速度法规, 开始, 和当前大型电动机转换器的读数.

5. 支持左右轨道频率转换器速度法规, 开始, 正面, 后退, 左右控制.

6. 支持左右轨道频率转换器的线性校正,以使机器行走

直线.

7. 支持绳锯自动切割功能, 自动调节左右轨道速度

实时根据大电机当前信息.

8. 还兼容直接IO输出控制电机启停, 和模拟电压输出

电机速度控制.

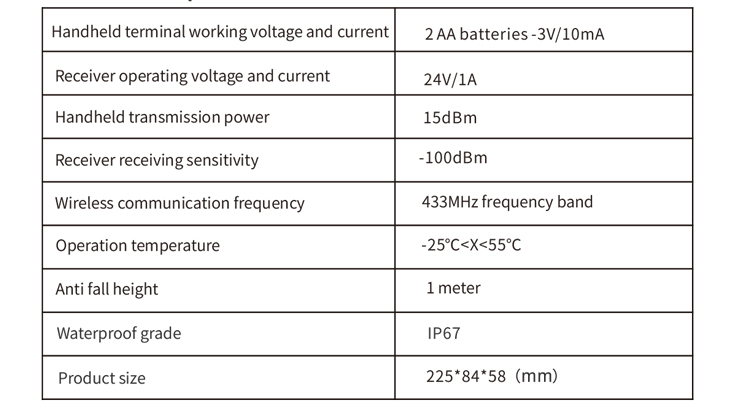

3. 产品规格

4. 产品功能介绍

笔记:

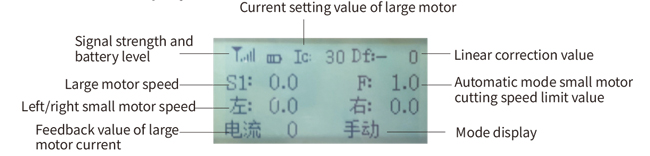

①屏幕显示:

②模式开关:

③启用:

组合按钮, 有些操作需要按下启用按钮以进行操作,详细信息请参阅每个开关的说明.

④大电机开关:

使用3速复位开关, 拉动此开关可以控制大电动机的前进和反向旋转. 发布后, 国家将保留, 屏幕上将有相应的显示器. S1↑箭头表示正转, S1↓箭头表示反向旋转.

⑤小型电动机向前/反向开关:

小电机前面装有3档自锁开关. 按下启用按钮并拉动此开关可以控制小电机前进和后退, 屏幕上会出现相应的显示。↑↑箭头代表前进, ↓↓箭头代表向后.

⑥ 直线校正:

使用多转弯编码器旋钮, 按启用按钮, 向右转动旋钮, 并显示直线校正: DF: 左旋钮增加 1 每转单位, 和左边

电机速度增加 0.1 单元; 转向左旋钮, 直线校正显示: DF: 在右侧, 旋钮每转一圈都会增加 1 单元, 右侧电机的速度增加

经过 0.1 单元.

⑦小电机转动开关:

使用3速复位开关, 手动操作时, 可以控制小电动机以左或右转. 一旦发布, 遥控器会自动停止此动作. 前进状态下, 当这个开关打开时, 屏幕上会出现相应的显示. ←↑箭头表示左转, ↑→箭头表示右转。倒车模式时, 转动此开关,屏幕上会出现相应的显示. ←↓箭头表示左转, ↓→箭头表示右转.

⑧大型运动速度法规:

使用多转弯编码器旋钮, 旋转 1 每次网格, 大电机的速度值大约变化 0.2 单位. 快速旋转可以快速修改大电机的速度值.

⑨ 小电机调速:

使用多转弯编码器旋钮, 在手动模式下, 按下启用按钮,然后一次旋转一个网格,左右小电机的速度值变化约 0.1 单位, 快速旋转可以快速修改小电机的速度值。在自动模式下, 按下启用按钮并一次旋转一个网格,小电机的速度限制值F变化约 0.1 单位. 快速旋转可快速修改小电机的速度限制值.

⑩ 遥控电源开关

遥控显示屏幕已打开.

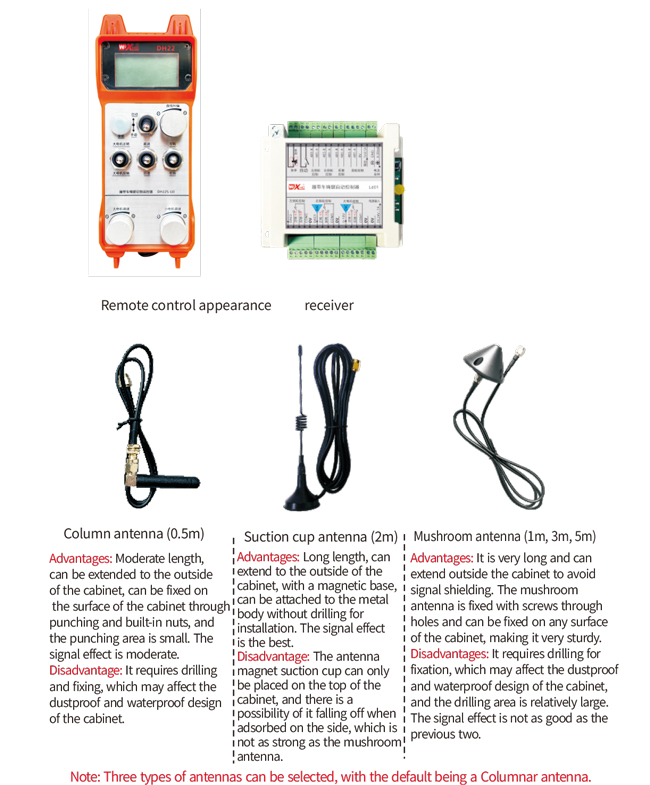

5. 产品配件图

6. 产品安装指南

6.1 产品安装步骤

1. 通过背面卡扣将接收器安装到电气柜中, 或通过接收器四个角的螺孔安装到机柜中.

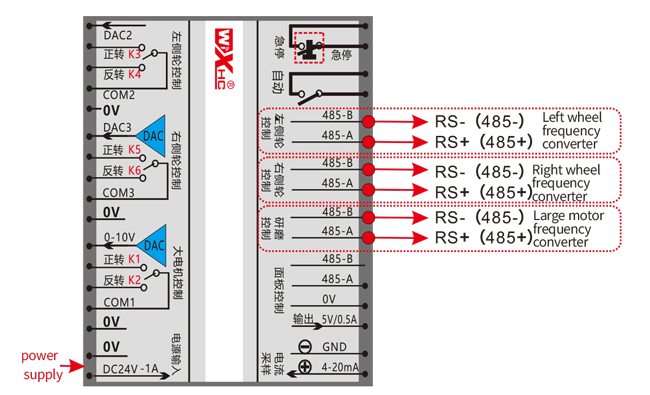

2. 请参阅我们的接收器接线图并将其与您的现场设备进行比较. 通过电线将设备与接收器连接.

3. 固定好接收器后, 需连接接收器配备的天线,并将天线外端安装或放置在电气柜外. 建议将其放在电柜的顶部以获得最佳信号效果. 禁止将天线不连接或放置在电气柜内, 因为这可能会导致信号无法使用.

4. 最后, 将电池安装到遥控器上, 拧紧电池盖, 并打开遥控器电源开关. 遥控器显示屏显示正常后

工作界面, 可进行远程控制操作.

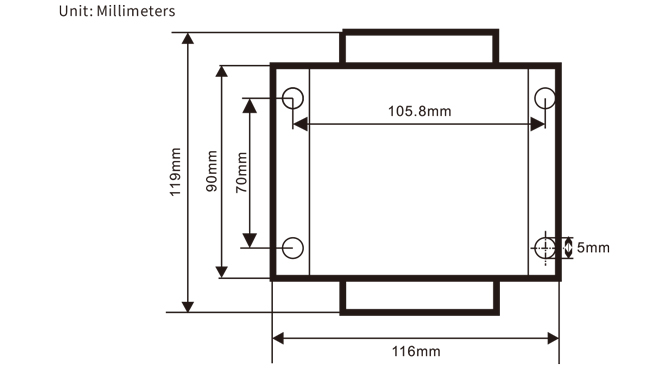

6.2 接收器安装尺寸

6.3 接收器接线参考图

7. 产品操作说明

7.1 遥控参数设置

远程控制后台参数输入方法:

将模式开关转到手动模式, 调整小电动机的速度 25 两侧, 或者 0, 10, 20, 40, 50 在所有方面, 并连续将大电机的前进开关拨到上方 3 次数和次数 3 时代;

使用 “小运动速度控制” 旋钮翻页, 按启用按钮, 然后转动小电机调速旋钮修改参数. 修改后, 将页面转到末尾,选择 “节省” 退出, 然后按启用按钮退出菜单;

参数如下:

最大电流: 大电机电流反馈范围, 设定范围15-200A, 默认 100;

速度控制参数: 自动模式, 小电机自动加速或减慢,速度越快, 设定范围 200-1500, 默认 800;

减速参数: 设置允许电机转速变化的上限. 当电流超出此值时, 将会发生减速. 越小, 左右电机减速越快, 与一系列 05-12 和默认值 06;

加速A1: 电机转速越大, 增加得越快, 与一系列 00-06 和默认值 01;

减速A2: 电机转速越大, 减少得越快, 与一系列 00-06 和默认值 02;

启用速度法规: 小电机调速是否需要开启? 00 不启用, 01 使, 默认是 01;

开始自锁: 松开正反转开关后大电机是否自动保持自锁? 00 不成立, 01 持有, 默认 01

最大步行: 左右电机最高转速, 范围 10-100, 默认 50;

切割电流: 最大切割电流, 屏幕上显示IC值, 范围 15-160, 默认 30,

对应IC: 30 显示在屏幕上. 该参数的上限为 80% 最大电流;

默认速度限制: 开机时默认小电机自动切割速度在以下范围内 0-100, 默认为 10. 屏幕显示F1.0, 并且该参数仅在最大步行设置为时才准确 50.

自动模式: 设置为 00, 自动/手动开关是模式开关. 设置为 01, 自动/手动开关设置到自动位置, 显示屏显示灯光, 并且接收器上的自动终端输出关闭. 当设置为手动时, 自动输出端子断开;

限速偏差: 小电机自动切割速度上限范围为 00 到 200, 默认为 60 以及相应的显示 6.0 在屏幕上; 显示值上限=速度限制偏置x 0.1;

最大主机: 大电机最高转速, 范围 10-100, 默认 50;

M总线设备 (强制的): 大电机变频器型号的选择, 范围 00-03, 默认 03;

00- Shanghai Xielin 01-Fuji

02-英威腾03-汇川技术(中辰), 罗比克(Robicon)

SBU设备 (强制的): 小型电动机转换器模型选择, 范围 00-05, 默认 03;

00- Shanghai Xielin 01-Fuji

02-英威腾03-汇川技术(中辰), 罗比克(Robicon)

04-anchuanda 05-NONE

7.2 转换器的参数设置

1. 命令源选择: 通信命令频道

2. 主要频率源选择: 给出的沟通

3. 波特率: 19200

4. 数据格式: 没有验证, 数据格式<8-N-1>

5. 本地地址: 将左频转换器设置为 1, 正确的频转换器 2, 和

大型电机变频器 3

7.3 遥控操作说明

1. 在机器上电源, 打开遥控器, 进入远程控制后台, 设置

远程控制后台参数, 主要设置小电机和大电机频率

转换器型号: (如果机器制造商已经设置了此步骤,则跳过此步骤);

2. 设置频转换器的参数 (如果机器制造商

已经设置了);

3. 将遥控器设置为手动模式, 然后使用遥控器将机器移动到

工作位置;

4. 在手动模式下, 设置大电机的切割电流IC和大电机的转速

5. 切换到自动模式并设置小电动机的切割速度限制F值;

6. 在自动模式下, 将大型电机开关向前转动以启动大电动机, 然后转动

小电机切换前进或后退, 遥控器进入自动切割

开始切割模式.

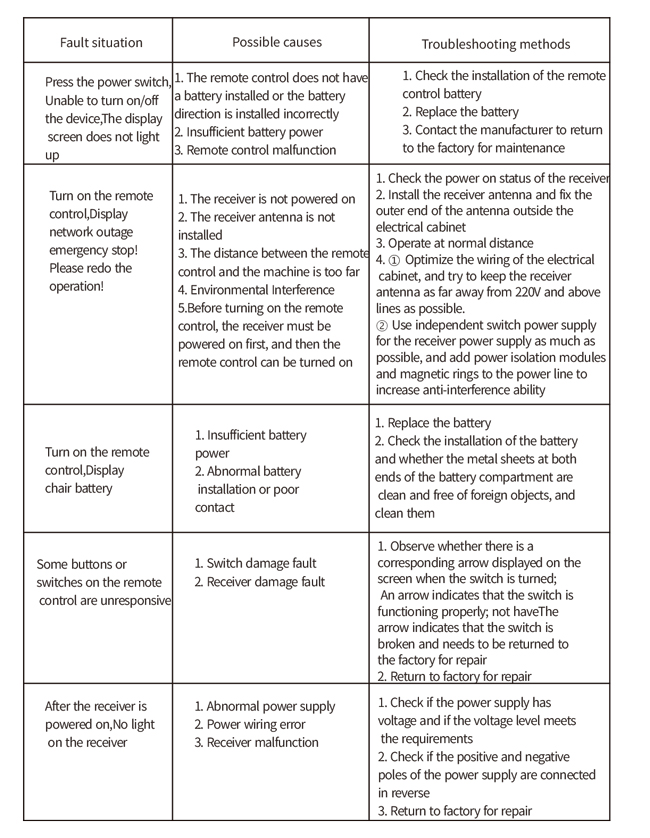

8.产品故障排除

9.维护

1. 请在室温和压力下在干燥的环境中使用它以延长其使用寿命.

2. 请避免在雨水和水泡等异常环境中使用以延长使用寿命.

3. 请保持电池舱和金属弹片区域清洁.

4. 请避免由于挤压和下降而损坏遥控器.

5. 如果很长一段时间没有使用, 请取出电池并将遥控器和电池存放在干净的地方

和安全的地方.

6.在存储和运输过程中, 应注意水分和电击性.

10. 安全信息

1. 请在使用前仔细阅读说明,并禁止非专业人员操作.

2. 电池电量过低时请及时更换电池,以免造成错误

电量不足, 这可能导致遥控器无法操作.

3. 如果需要维修, 请联系制造商. 如果损害是由自修理造成的, 制造商

将不提供保修.